Discover Durable, High-Performance Flexible Metal Hoses for Industrial, Commercial, and Residential Applications – Built to Last

Thread Connection

Flange Connection

Union Connection

Cam-lock Connection

Tri Clamp Connection

Weld Connection

Fire metal hose

PTFE Inner

Using high-quality rubber raw materials

We purchase high-quality rubber raw materials from high-quality raw material suppliers and control the quality from the source.

Factory independent rubber refining

Our factory has its own rubber refining equipment, which can make different rubber ratios according to customer requirements, and can also control the rubber quality from the source

Rubber cutting into slices in each pcs

We have an automatic rubber slicer, which can cut rubber into uniform thickness and size, making it easier to process later.

Cutting Flexible Metal Hoses to Length

We cut flexible metal hoses to the specified length as per the client’s requirements. Each hose cut is smooth and free of burrs. With strict quality control, we provide you with durable and reliable flexible metal hose products.

Metal Hose Flange Welding Processing

Our metal hoses utilize TIG (Tungsten Inert Gas) welding technology. We employ advanced welding techniques to ensure a secure connection between the flange and the hose, providing excellent sealing performance.

Rubber cutting into slices in each pcs

We perform comprehensive testing on each flexible metal hose, including pressure tests, sealing tests, and fatigue tests, to ensure its reliability and durability in high-intensity, high-frequency operating environments.

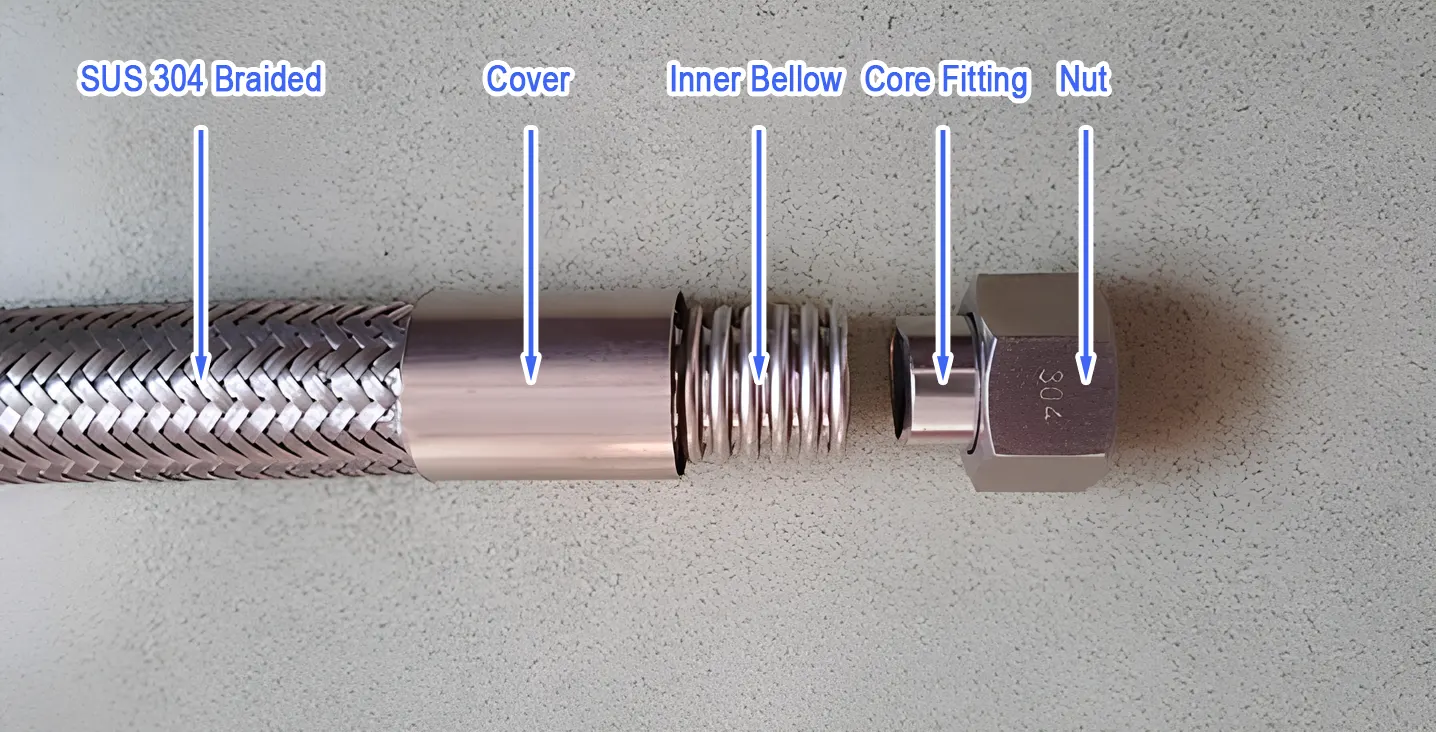

To help users gain a deeper understanding of our metal hoses, we have disassembled them to provide a more intuitive view of the internal structure and the materials used.

Some manufacturers stretch their corrugated tubes excessively to reduce costs, leading to decreased flexibility and a shorter lifespan for the metal hoses.

At our factory, we consistently prioritize quality by using a tight corrugation design to ensure every metal hose boasts:

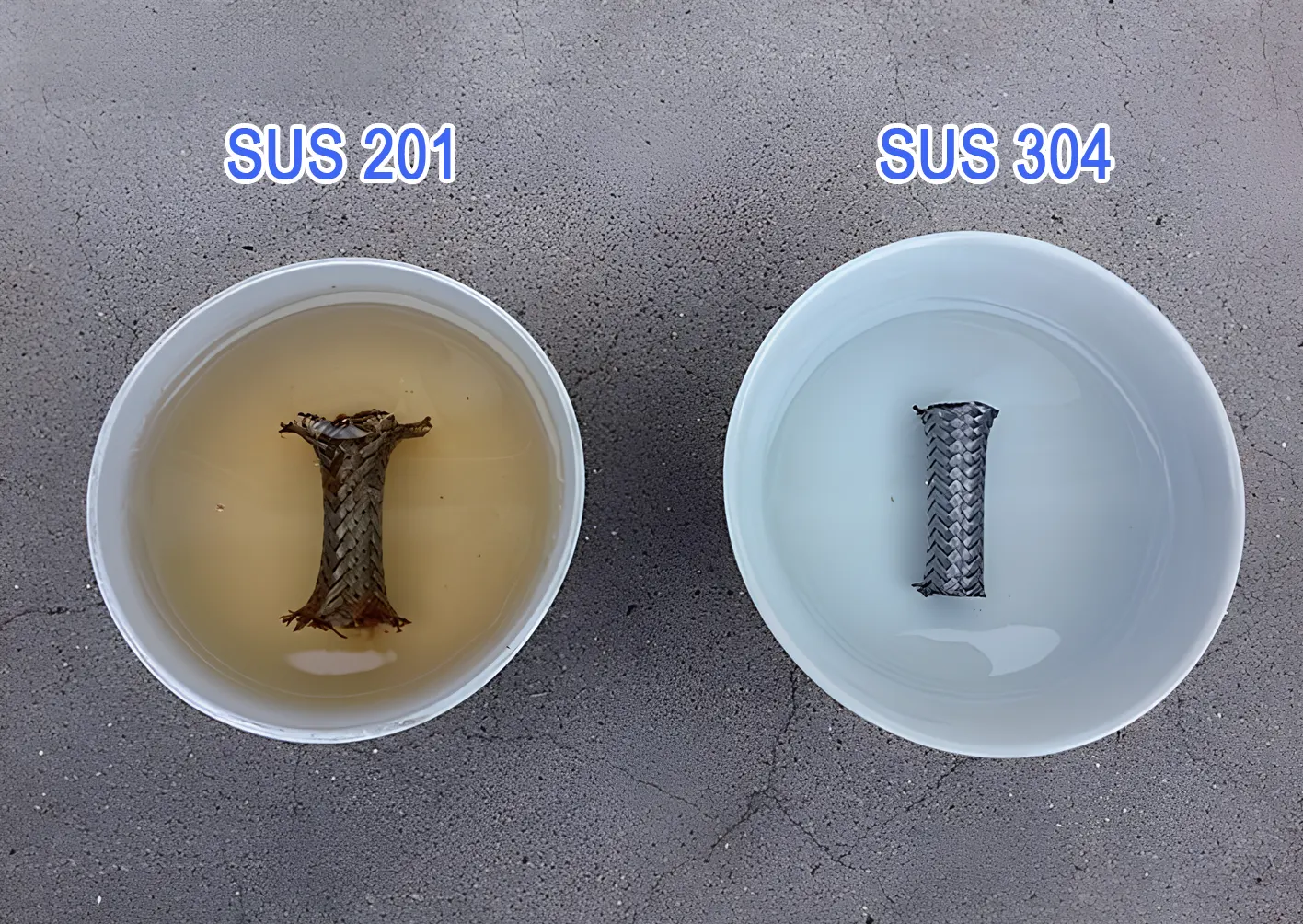

Still Struggling with Rusting and Short Lifespan of Ordinary Metal Hoses?

Crafted from premium 304 stainless steel, our metal hoses are rust-resistant for life!

Our flexible metal hoses are designed without stretched corrugated tubing, ensuring they can withstand higher pressures and temperatures. With denser wire braiding, we enhance the hose’s durability and tensile strength. The weight of each hose is a true reflection of its superior quality, demonstrating our meticulous attention to every detail. Choosing our flexible metal hoses means choosing a reliable product with high strength and outstanding performance.

True flexibility comes from a commitment to quality! Our flexible metal hoses feature un-stretched corrugated inner tubes, perfectly preserving their excellent flexibility. They can easily bend and adapt to various complex installation environments. In contrast, standard flexible metal hoses lose their elasticity and become stiff due to excessive stretching, failing to meet high flexibility demands.

We have designed a 4cm thick protective cover for our flexible metal hoses, while many products in the market are only 2.3 cm. The thicker cover provides a stronger connection, ensuring each hose remains stable under pressure and is less likely to loosen or detach. We are committed to providing high-quality flexible metal hoses, enhancing product reliability and durability for a more secure and lasting performance.

Sample Subtitle

Our flexible metallic hose have obtained ISO9001 certification and WARS certification.

Our flexible metallic hose can issue MTC reports.

In addition, if you need From E or CO certificate, we can also provide it.

Got questions about our products or services? Our FAQ section provides quick and clear answers to common queries. Dive in to learn more about rubber virbation bellow expansion joint. and how we can serve your needs.

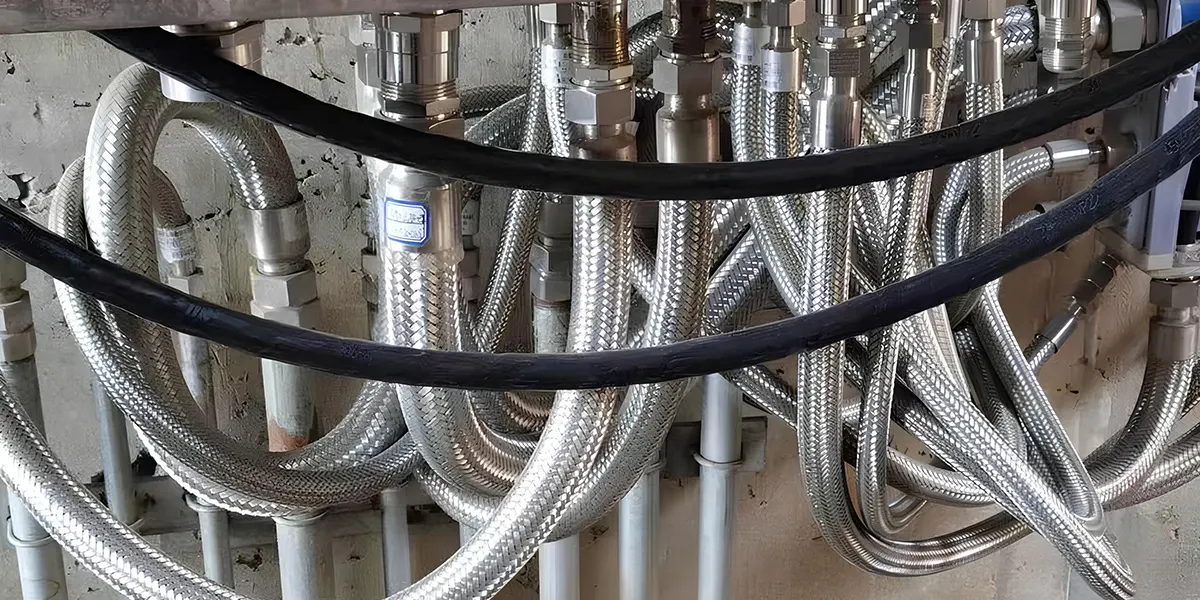

We specialize in application and design, dedicated to helping our customers identify the most cost-effective solutions. Our engineering and manufacturing teams have extensive experience across sectors such as petrochemical, refining, nuclear energy, desalination, and HVAC. With deep expertise in meeting complex documentation requirements, we are proficient in non-destructive testing and comprehensive project testing, ensuring the highest quality and reliability in every project we undertake.

Before starting to use our services, please fill in the following form to let us know which type of stainless steel duct system you want to import from China.

WhatsApp us

Choose Caijie

Stretch Your Budget, Not Your Standards !

Before starting to use our services, please fill in the following form to let us know which type of stainless steel duct system you want to import from China.

Once we receive the detailed information regarding your request, your assigned customer representative will contact you shortly.

If you need help, please email us at sales1@caijie-tech.com.