Rubber expansion joints are essential components in industrial piping systems, designed to absorb movement, vibrations, and thermal expansion. One of the most common questions asked is, “How long do rubber expansion joints last?” The lifespan of these joints can vary based on several factors, including the materials used, operating conditions, and maintenance practices. On average, rubber expansion joints can last anywhere from 5 to 20 years.

Factors Affecting the Lifespan of Rubber Expansion Joints

The durability of rubber expansion joints depends on various factors:

- Material Quality: High-quality materials such as EPDM or nitrile generally result in longer-lasting expansion joints.

- Operating Conditions: Extreme temperatures, high pressure, and exposure to harsh chemicals can reduce the lifespan of rubber expansion joints.

- Maintenance: Regular inspection and maintenance help identify wear and tear, allowing for timely replacements and extending the life of the joints.

How to Ensure the Longevity of Rubber Expansion Joints

To maximize the lifespan of rubber expansion joints, it’s essential to:

- Conduct regular inspections for signs of wear or damage.

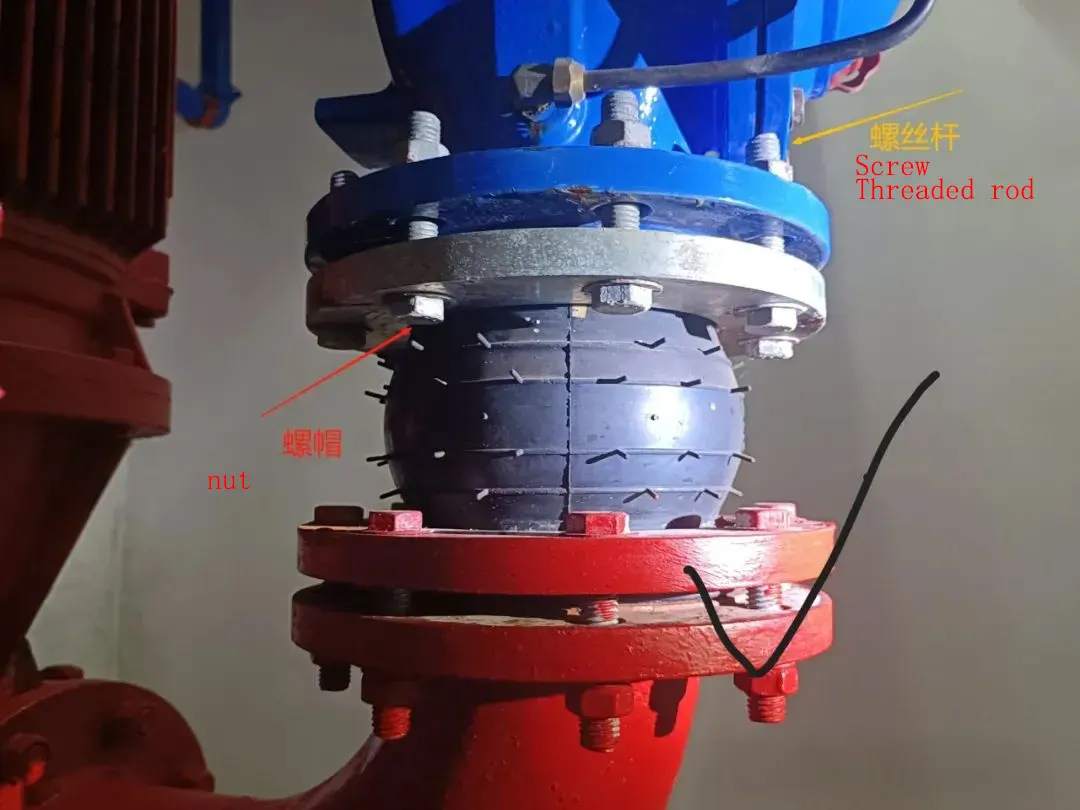

- Ensure that the joints are installed correctly, according to manufacturer guidelines.

- Monitor the operating environment and make adjustments to minimize stress on the joints.

In conclusion, rubber expansion joints typically last between 5 and 20 years, depending on material quality, operating conditions, and maintenance. Proper care and monitoring can significantly extend their lifespan, ensuring the continued efficiency and integrity of your piping system.