When designing and maintaining piping systems, it’s important to choose the right expansion joint material to ensure optimal performance. The question of “What material can be used as expansion joint?” can be answered by considering various materials, each offering unique benefits based on the specific requirements of the piping system. The right choice depends on factors such as temperature, pressure, chemical exposure, and flexibility needs.

Common Materials Used for Expansion Joints

Several materials can be used as expansion joints, each suitable for different types of applications:

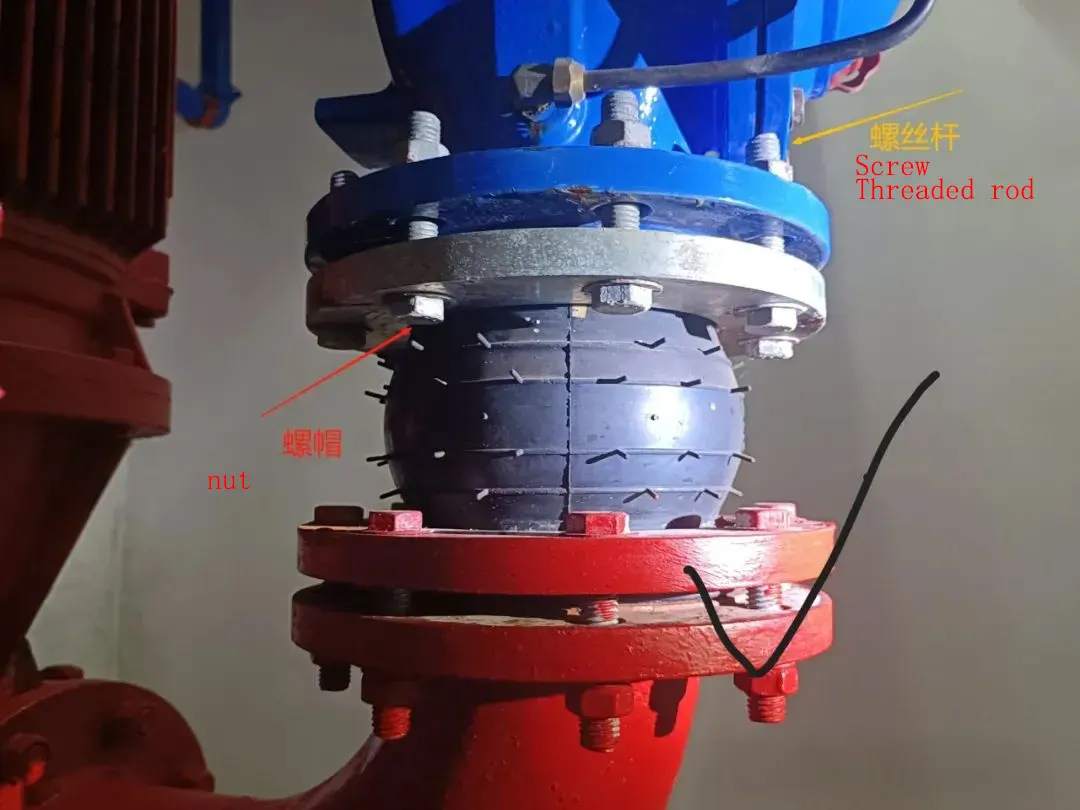

- Rubber: Rubber expansion joints are commonly used for general piping systems where flexibility, vibration absorption, and thermal expansion resistance are required. They are typically used in HVAC systems, plumbing, and water pipelines. Rubber is cost-effective and provides reliable performance in medium-pressure applications.

- Metal: For high-temperature, high-pressure, and corrosive environments, metal expansion joints made from materials such as stainless steel or alloyed metals are ideal. They provide durability and flexibility in industries like oil and gas, chemical processing, and power plants.

- Fabric: Fabric expansion joints are lightweight, flexible, and easy to install, often used in applications with space constraints. They can absorb vibrations and movement, making them suitable for low-pressure systems, such as in some HVAC applications and gas systems.

- PTFE (Polytetrafluoroethylene): PTFE expansion joints are designed for extreme chemical resistance, making them perfect for chemical processing industries. They handle both high temperatures and aggressive chemicals, offering durability in harsh environments.

- Elastomers: Elastomers like EPDM (Ethylene Propylene Diene Monomer) or Neoprene offer resistance to ozone, weathering, and heat. They are often used in outdoor installations or where high durability is required without the need for metallic components.

Factors to Consider When Choosing the Material for Expansion Joints

When selecting a material for an expansion joint, consider the following:

- Temperature Range: High temperatures might require metal or PTFE expansion joints, while rubber joints are better for moderate conditions.

- Pressure: For systems with high-pressure demands, metal expansion joints are the best choice due to their strength and durability.

- Chemical Resistance: If the piping system deals with aggressive chemicals, PTFE or elastomers would be more suitable due to their excellent chemical resistance.

- Flexibility and Movement: Rubber and fabric joints provide greater flexibility, which is ideal for systems that experience significant movement.

Conclusion: What Material Can Be Used as Expansion Joint?

In conclusion, the material used for expansion joints varies based on application-specific requirements. Whether you need the flexibility of rubber, the durability of metal, or the chemical resistance of PTFE, the right material ensures the long-term integrity and efficient performance of the piping system. By understanding the unique properties of each material, you can make an informed decision for your system’s needs.