Metal hoses offer excellent flexibility and outstanding resistance to high temperature, corrosion, high pressure, and fatigue. Compared with plastic hoses, they are safer and have a longer service life. As a high-quality flexible conduit, metal hoses are widely used in modern industrial pipelines, mainly in aerospace, electric power and transportation, construction and steel, and petrochemical fields.

See our flexible metal hose product page for specifications and options.

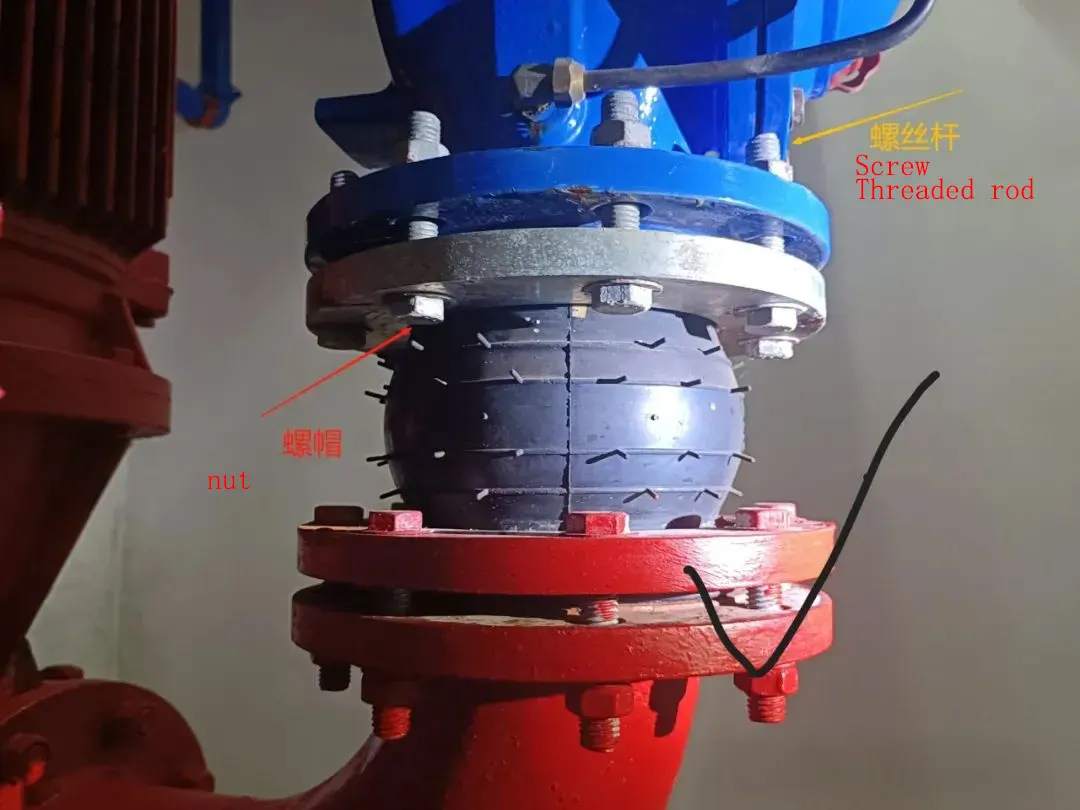

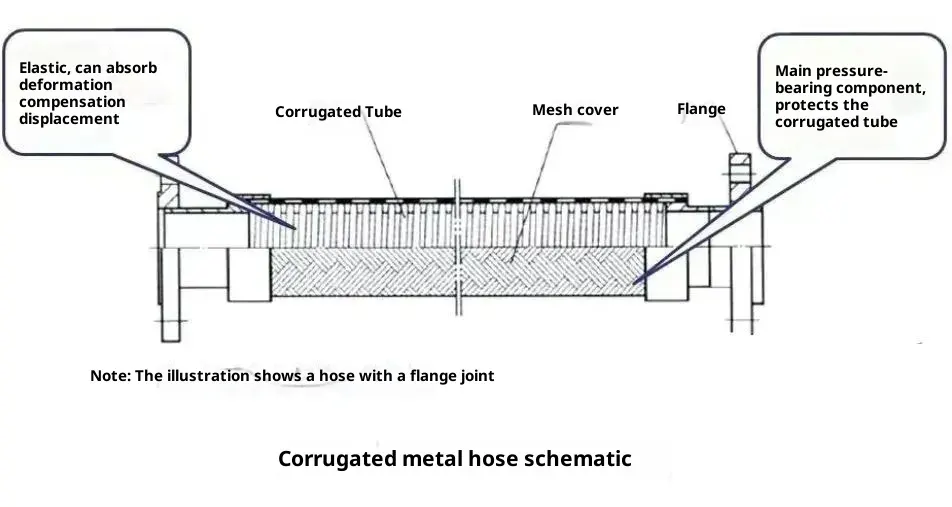

Corrugated metal hoses are composed primarily of a bellows, a braid, and end fittings, as shown in the figure.

I. Classification of Corrugated Metal Hoses

According to SH/T 3412-2017 – Specification for Selection, Inspection and Acceptance of Metal Hoses for Petrochemical Piping, metal hoses are categorized as general-purpose, seismic, and cryogenic types. They are widely used in petrochemical and coal-chemical pipeline projects to compensate for pipeline displacement and foundation settlement, provide seismic protection, and absorb vibration.

For product-level details, visit our flexible metal hose range.

1. General-Purpose Metal Hoses

General-purpose metal hoses are used in standard applications. The flexible element typically consists of a bellows and a wire braid. Installed in liquid transport systems as flexible pressure components, metal hoses compensate for relative displacement between pipelines and equipment nozzles, absorb vibration energy, and provide vibration damping and noise reduction.

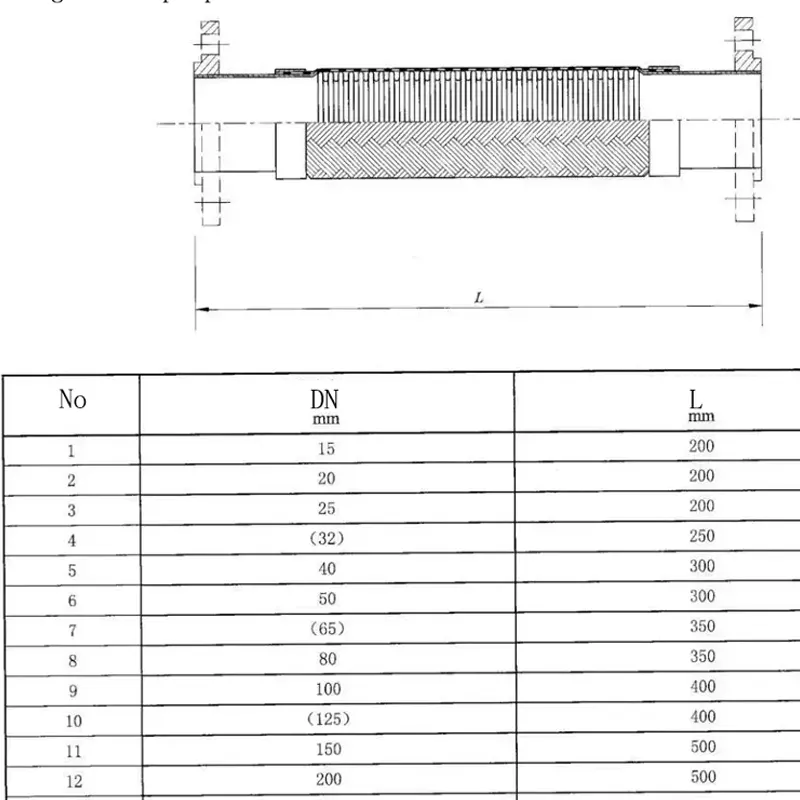

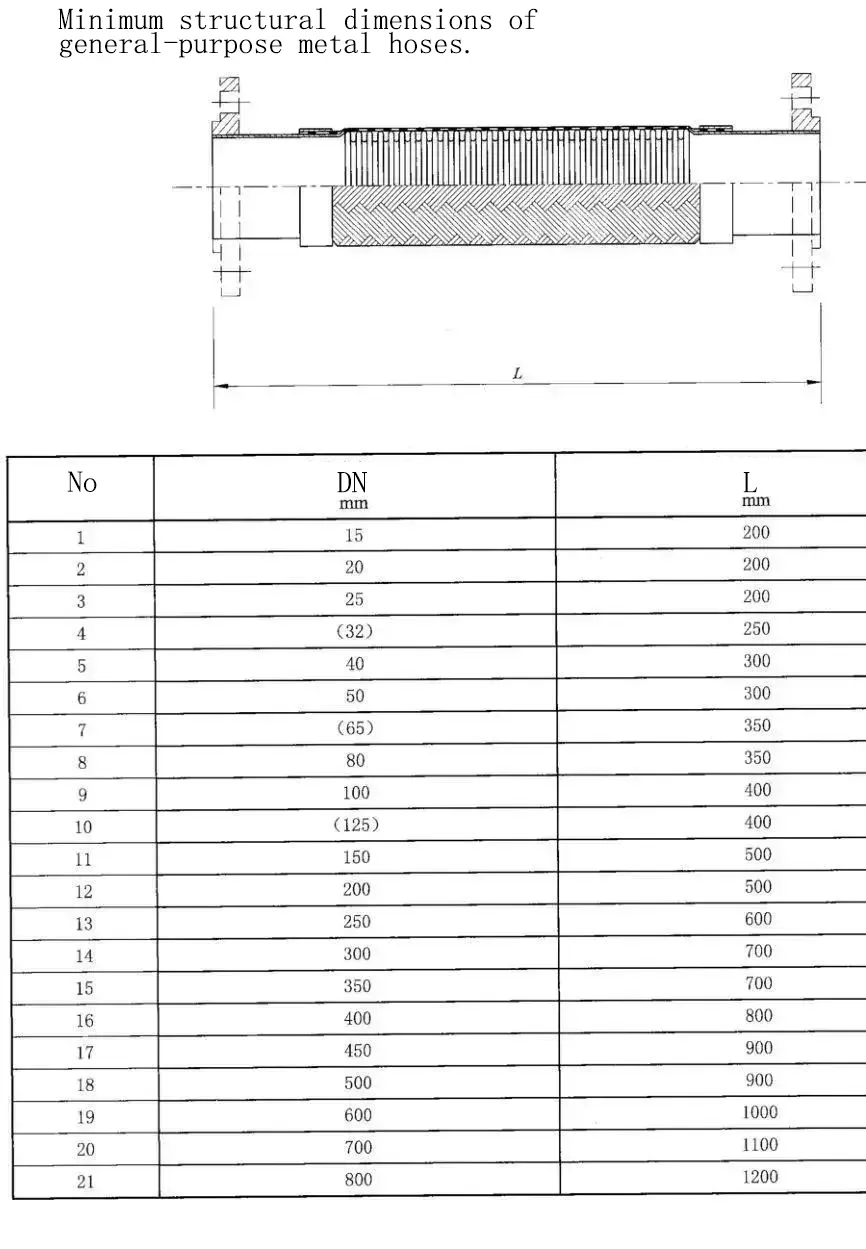

Minimum structural dimensions for general-purpose hoses per SH/T 3412-2017:

2. Seismic Metal Hoses

Used on storage tank inlet and outlet lines, the flexible element generally consists of a bellows with a steel strip braid, and—if required—armor rings installed in the bellows valleys. Their main functions are to reduce earthquake damage to tanks, compensate for tank foundation settlement, accommodate thermal expansion and contraction of pipelines, and correct installation deviations.

Per GB 50160-2008 (2018 edition) – Fire Protection Design Specification for Petrochemical Enterprises, clause 6.2.25: “Flexible connections shall be used for storage tank inlet and outlet pipelines.” Considering settlement during tank water tests, non-uniform settlement, and seismic settlement, seismic metal hoses or expansion joints are typically required at tank nozzles.

Per TCCSAS 023-2022 – Specification for the Installation and Use of Emergency Shut-off Valves in Hazardous Chemical Enterprises, clause 5.5.4: “When flexible connections are provided on storage tank inlet and outlet pipelines, the emergency shut-off valve shall be installed between the tank and the flexible connection.” Due to nozzle loading and potential valve settlement with the tank shell, the emergency shut-off valve requires spring supports.

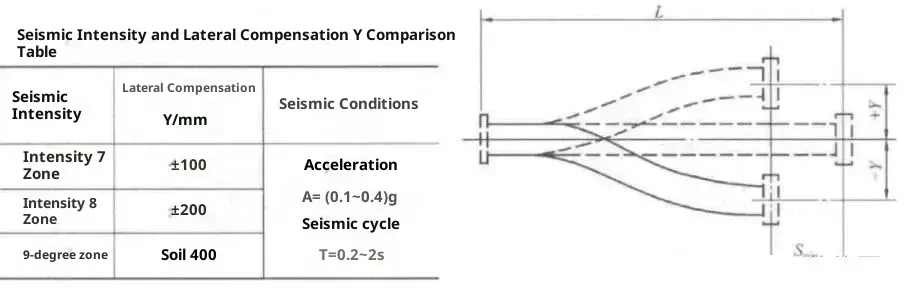

Selection method for seismic hoses: Determine the required lateral compensation based on the site’s seismic fortification intensity, then use the nominal pipe size to look up the minimum structural dimensions that meet that lateral compensation.

- Seismic fortification intensity: see GB 50011-2010 (2016 edition) – Code for Seismic Design of Buildings, Appendix A, or the project geotechnical report.

- Minimum structural dimensions for seismic hoses per SH/T 3412-2017:

3. Cryogenic Metal Hoses

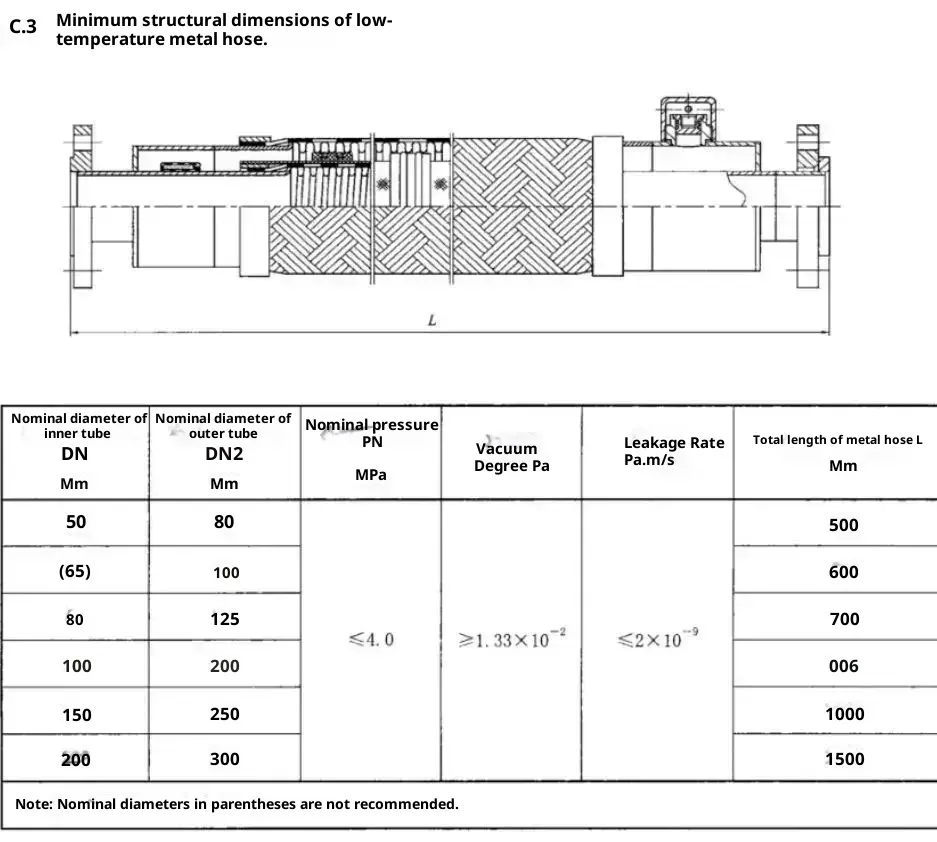

Cryogenic metal hoses are used to convey low-temperature media and typically adopt a double-wall flexible structure with vacuum drawn between the layers.

Minimum structural dimensions for cryogenic hoses per SH/T 3412-2017:

Per GB 50160-2008 (2018 edition) clause 7.2.18: Hoses shall not be used on pipelines for liquefied hydrocarbons, liquid chlorine, or liquid ammonia; non-metallic hoses shall not be used on flammable liquid pipelines.

II. Purpose and Principles of Metal Hose Installation

1. Purpose

In engineering applications, metal hoses are primarily used to provide thermal compensation, eliminate mechanical displacement, absorb vibration, reduce noise, allow flexible movement, and conveniently change the flow direction of fluids.

2. Principles (Petrochemical Units)

Metal hoses are typically provided under the following conditions:

2.1 Large Petrochemical Product/Feedstock Storage Tanks

Installing metal hoses on tank inlet and outlet lines helps prevent pipeline damage and product leakage due to foundation settlement or earthquakes, avoiding property loss and environmental pollution. This is especially important in seismically active regions.

2.2 Inlet/Outlet of Large Machines and Pumps

Equipment such as pumps, compressors, and centrifuges generate vibration and noise during operation, affecting project quality and personal health. For large machines, pumps, and centrifuges, metal hoses should be installed on the suction and discharge nozzles to damp vibration and reduce noise, improve quality, extend equipment life, and facilitate installation.

2.3 Tank Trucks and Oil Tankers

Loading arms for railway and road tank trucks and oil tankers commonly adopt metal hoses. Metal hoses enable sealed loading/unloading to reduce evaporation losses, while offering easy installation, removal, and mobility to simplify operations.

2.4 Electronic Weighing Equipment

In chemical units—especially polymerization units—batching is common and requires accurate measurement. Weighing vessels must not bear axial loads after installation. All connecting lines should use metal hoses for flexible connections to eliminate piping effects on weighing accuracy.

2.5 Equipment Requiring Frequent Disassembly or Process-Induced Displacement

For connections between mobile equipment (filters, filling machines, portable pumps or compressors) and fixed equipment or piping, metal hoses are recommended.

2.6 Others

Pipelines crossing building expansion joints should preferably use metal hoses to compensate for differential wall settlement. Where routing space is limited and operating temperature is high, metal hoses can be added at equipment nozzles to absorb expansion and eliminate thrust on the nozzles. Metal hoses also retain shape at low temperatures and offer good flexibility, making them widely used on cryogenic lines. Their excellent tightness makes them suitable for high-vacuum systems.

III. Selection of Corrugated Metal Hoses

Selection should comprehensively consider: medium properties, nominal diameter and pressure, end connection type, displacement mode, minimum bend radius, and length. Improper selection may cause premature failure, leading to serious personal injury or equipment accidents.

1. Type

- For compensating pipeline displacement, installation deviation, and foundation settlement, and for vibration absorption and noise reduction, annular corrugated metal hoses are recommended.

- For higher pressure where displacement/vibration occurs infrequently, helical corrugated metal hoses are recommended.

2. Medium Properties & Materials

Select suitable materials based on the medium’s corrosiveness and temperature.

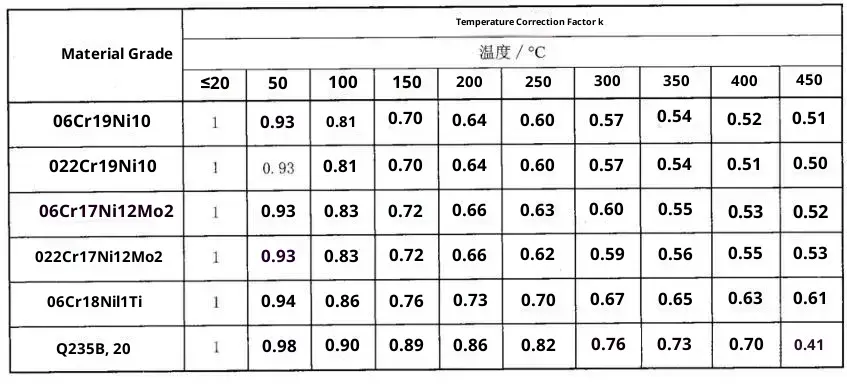

3. Temperature Correction Factor

Temperature correction factors for common materials of bellows, braid, and fittings are shown below.

Principle: Determine the correction factor separately for the bellows, braid, and fittings, then take the minimum value as the hose correction factor.

4. End Connection Types

Spherical seat, conical seat, union (flat-face) type, quick coupling, pipe thread, flange, and weld-end (plain end) types.

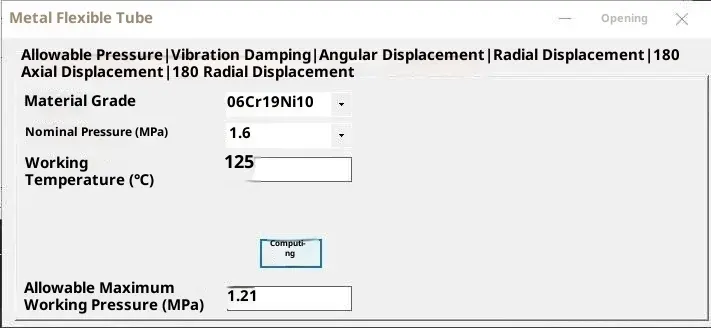

5. Maximum Allowable Working Pressure

6. Hose Length

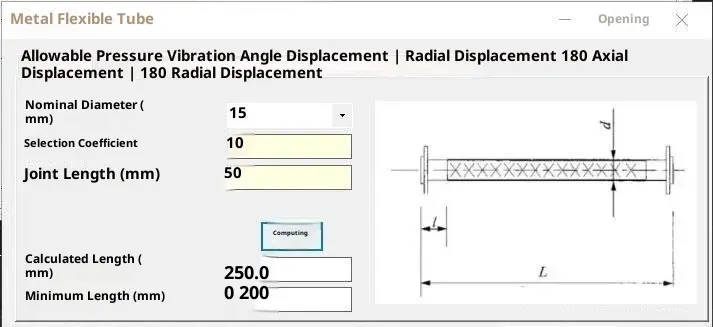

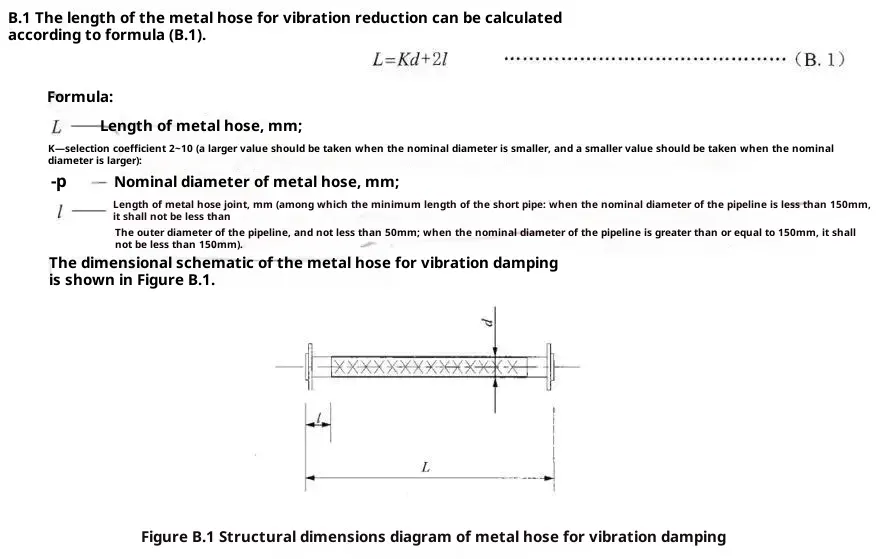

6.1 Length for Vibration Damping and Noise Reduction

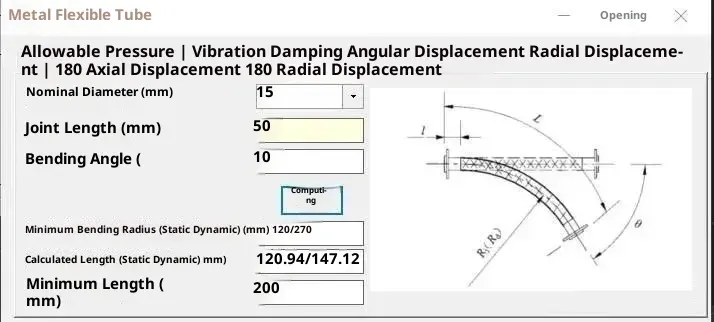

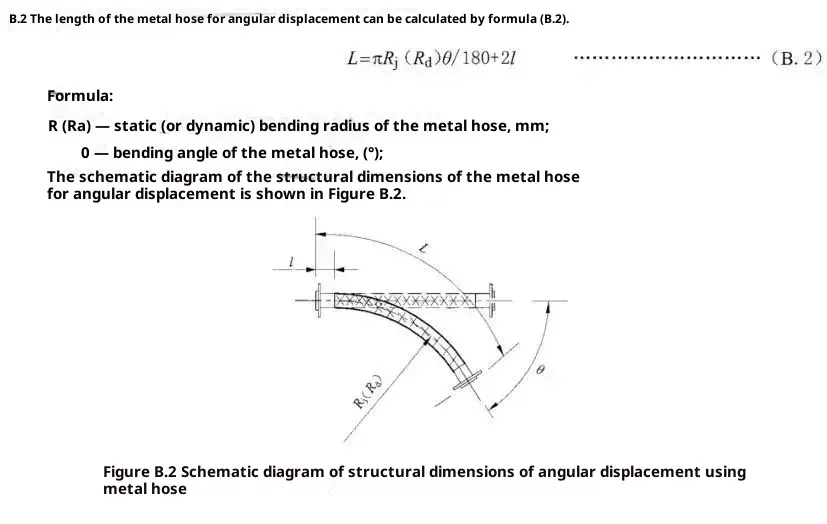

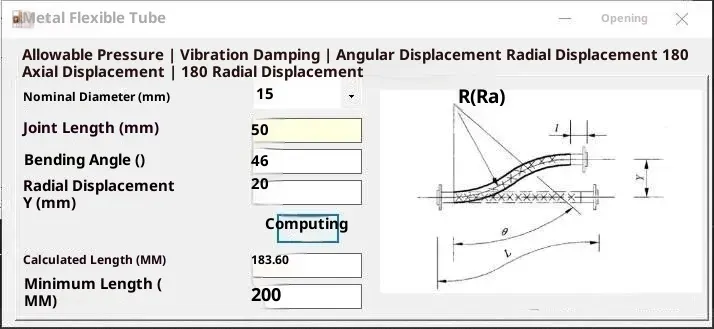

6.2 Length for Angular Displacement

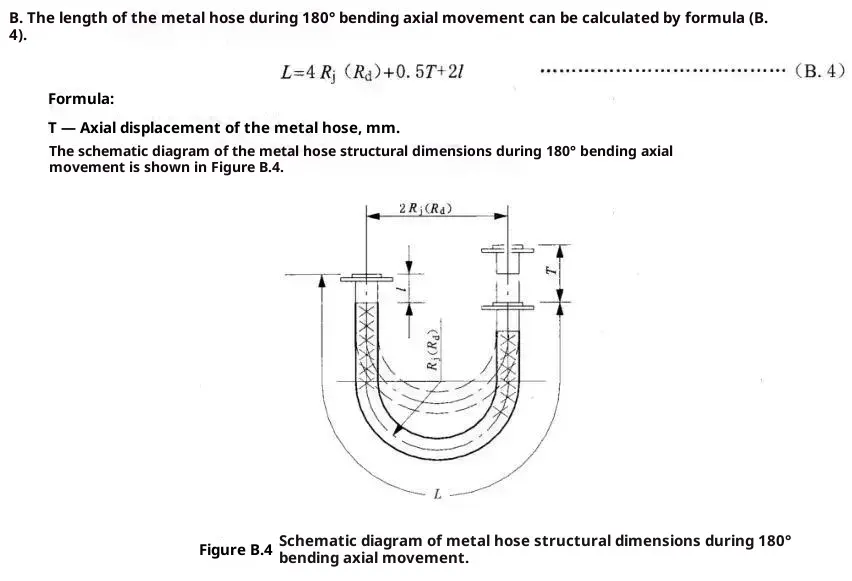

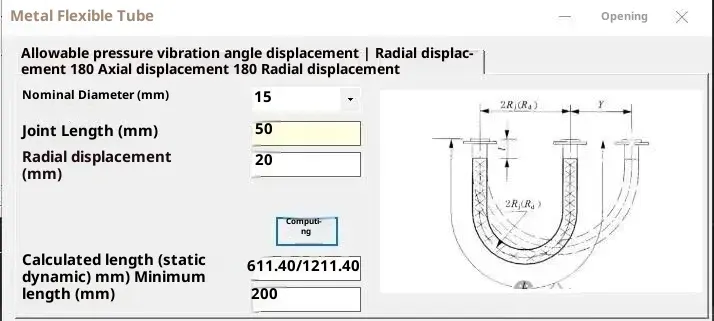

6.3 Length for 180° Bend with Axial Movement

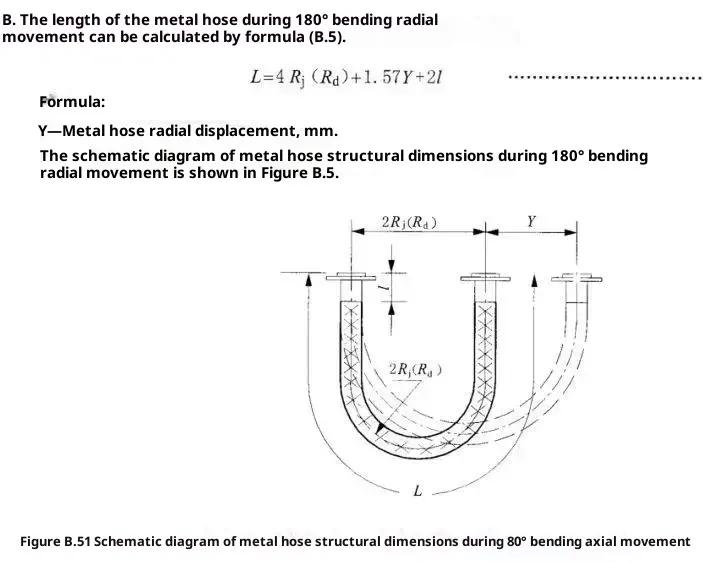

6.4 Length for 180° Bend with Radial Movement

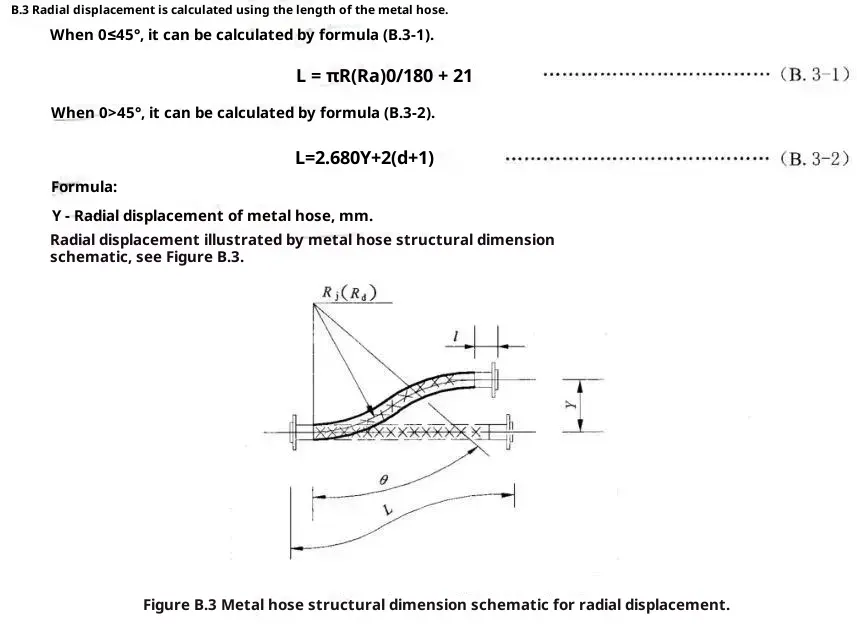

6.5 Length for Radial Displacement

IV. Installation Notes for Corrugated Metal Hoses

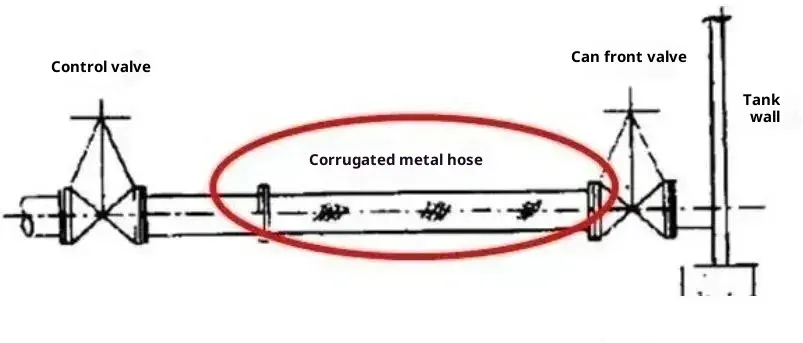

- Install the metal hose at the connection between the pre-tank valve and the pipeline to form a flexible link between the storage tank and the pipeline.

- When the pre-tank process line is pressurized, a control valve shall be provided when installing the metal hose.

- Prevent welding spatter from landing on the hose during installation.

- Do not use forcibly tightened flanges/bolts to eliminate installation deviations.

- After installation, the height of the metal hose above grade should be greater than its lateral displacement compensation.

- Do not install any supports or hangers on the metal hose.