Rubber expansion joints are typically made from a variety of elastomers, with material selection crucial for their performance and longevity in piping systems. The best rubber expansion joint material depends heavily on the application, the conveyed media, and the specific operating conditions. Choosing the right material ensures the joint can withstand the stresses of the system, including pressure, temperature, and chemical exposure.

Understanding Rubber Expansion Joint Materials

Rubber expansion joints are flexible connectors used to absorb movement, vibration, and thermal expansion or contraction in piping systems. They’re constructed from a range of elastomers, each offering unique properties suited to different environments. Key materials include:

| No | Rubber Type | Abbrev. | Heat Resistance Limit (°C) | Safe Heat Temperature (°C) | Cold Resistance Limit (°C) |

| 1 | Nitrile Rubber | NBR | 120 | 80 | -50 |

| 2 | Hydrogenated Nitrile Rubber | HNBR | 140 | 110 | -30 |

| 3 | Fluoroelastomer | FKM | 230 | 200 | -15 |

| 4 | Silicone Rubber | VMQ | 230 | 180 | -50 |

| 5 | Ethylene Propylene Diene Rubber | EPDM | 140 | 120 | -40 |

| 6 | Chloroprene Rubber (Neoprene) | CR | 110 | 70 | -40 |

| 7 | Acrylic Rubber | ACM | 160 | 140 | -20 |

| 8 | Butyl Rubber | IIR | 140 | 110 | -40 |

| 9 | Polyurethane Rubber | U | 100 | 70 | -30 |

| 10 | Chlorosulfonated Polyethylene Rubber | CSM | 130 | 100 | -30 |

| 11 | Epichlorohydrin Rubber (CO, ECO) | CO, ECO | 130 | 100 | -30 |

| 12 | Natural Rubber | NR | 80 | 65 | -50 |

| 13 | PTFE (Polytetrafluoroethylene) | PTFE | 260 | 250 | -100 |

Factors Influencing Material Selection

The selection of the appropriate rubber expansion joint material is a critical decision, influenced by several key factors:

Media Compatibility

The most crucial factor is the compatibility of the rubber with the fluid or gas being conveyed. Using incompatible materials can lead to joint failure, leakage, and system downtime. The “Summary Table” below provides a quick reference for common material and media compatibility.

Temperature Resistance

The operating temperature range of the system is another crucial consideration. Different elastomers have different temperature tolerances. Exceeding these limits can degrade the rubber, leading to premature failure.

Pressure Rating

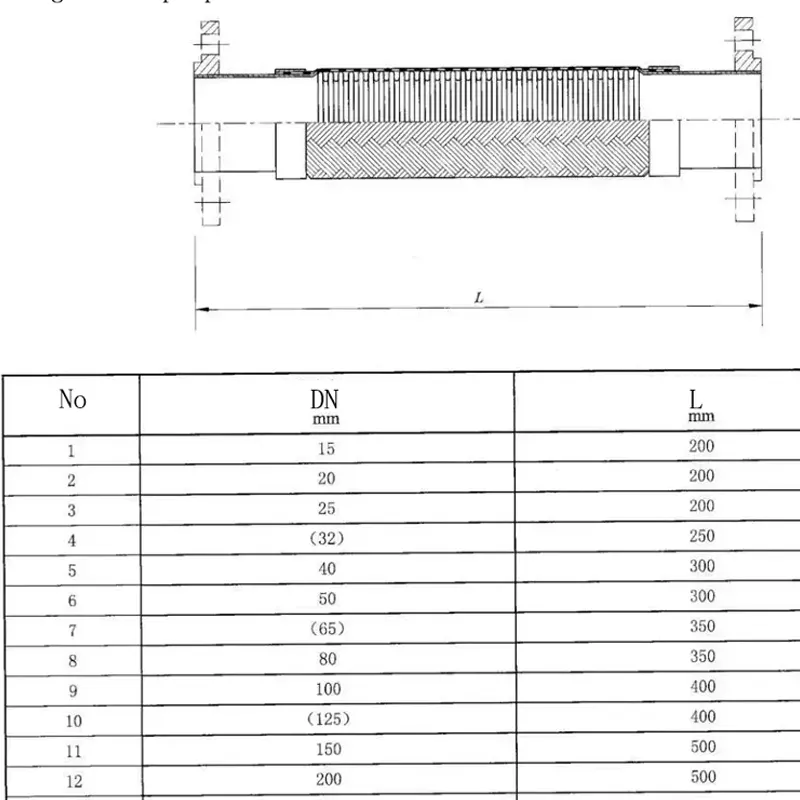

The joint must be able to withstand the operating pressure of the system. The material, along with the joint’s construction (including reinforcement), determines its pressure rating.

Movement Requirements

The amount of movement (axial, lateral, and angular) the joint needs to accommodate is also important. The flexibility of the chosen material and the joint’s design contribute to its ability to handle these movements.

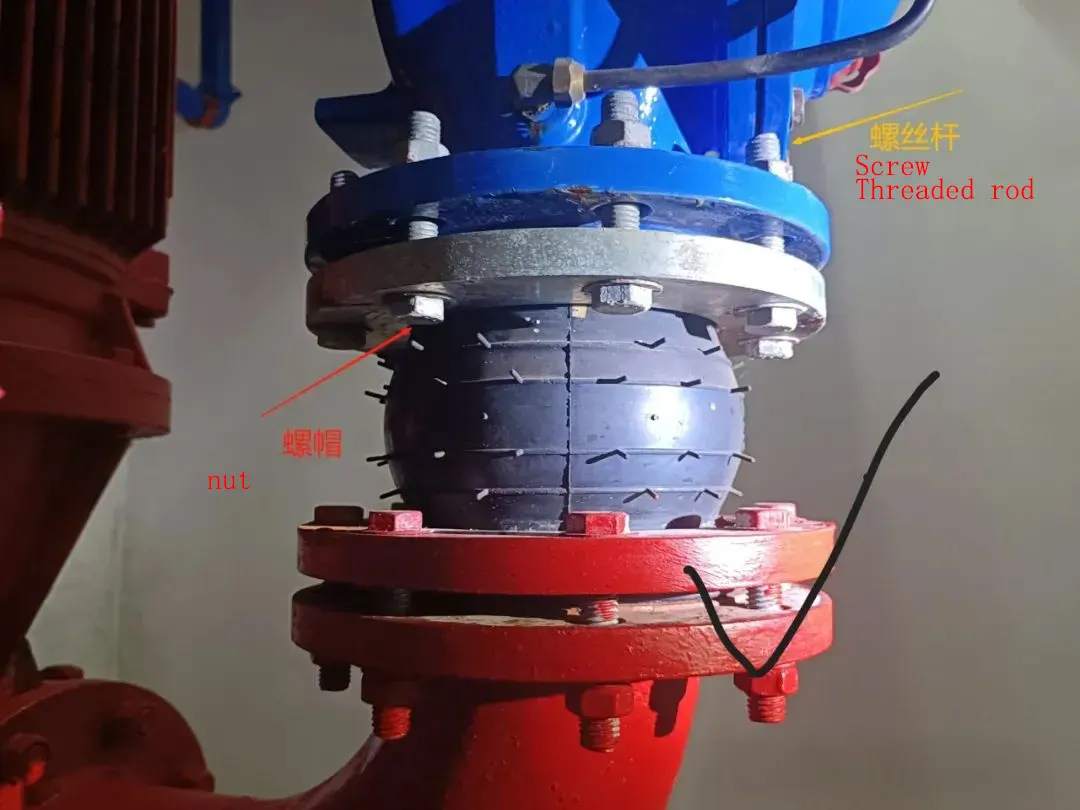

Reinforcements and Construction Details

Most rubber expansion joints utilize reinforcing materials to enhance their durability and pressure resistance. These reinforcements often include layers of synthetic fabric or steel cord. In applications involving highly corrosive substances, PTFE liners can be incorporated to further protect the elastomer and extend the joint’s lifespan.

Fabric and Steel Cord Reinforcement

These materials are embedded within the rubber to provide the necessary strength to withstand pressure and movement.

PTFE Liners

PTFE liners act as a barrier against aggressive chemicals, preventing them from contacting and damaging the underlying rubber.

Conclusion

Selecting the right rubber expansion joint material is paramount for the reliable and efficient operation of any piping system. By carefully considering the media being conveyed, the operating temperature and pressure, and the required movement capabilities, engineers can choose the optimal material to ensure long-lasting performance. Remember to consult with a qualified engineer or material specialist to ensure the best possible selection for your specific application.