Yes — stainless steel hoses offer significant advantages over other hose materials due to their superior durability, corrosion resistance, and ability to handle extreme temperatures and pressures. They are a robust and reliable choice for various applications, from industrial processes to residential use.Jump to:

What Makes Stainless Steel Hoses Stand Out?

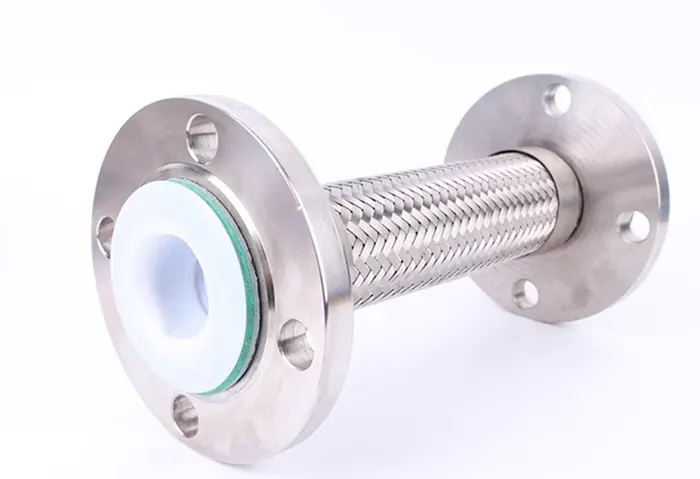

Stainless steel hoses are constructed from high-quality stainless steel, typically with a corrugated core for flexibility and often reinforced with a stainless steel braid for added strength. This unique construction provides several key benefits:

Superior Corrosion Resistance

One of the most significant advantages of a stainless steel hose is its exceptional resistance to corrosion. Unlike hoses made from materials like rubber or PVC, stainless steel can withstand exposure to harsh chemicals, saltwater, and other corrosive substances without degrading. This makes them ideal for applications in the chemical, marine, and food and beverage industries, where exposure to corrosive elements is common.

High-Temperature and Pressure Tolerance

Stainless steel hoses are designed to operate reliably under extreme conditions. They can withstand very high temperatures and pressures, making them suitable for demanding applications such as steam lines, hydraulic systems, and industrial processes. This resilience ensures that these hoses maintain their integrity and performance, even in challenging environments.

Durability and Longevity

The robust construction of a stainless steel hose contributes to its long lifespan. They are less prone to leaks, bursts, and abrasion compared to non-metallic hoses. This durability translates to reduced downtime, lower maintenance costs, and a safer operating environment. The longevity of stainless steel hoses makes them a cost-effective solution in the long run.

Flexibility and Versatility

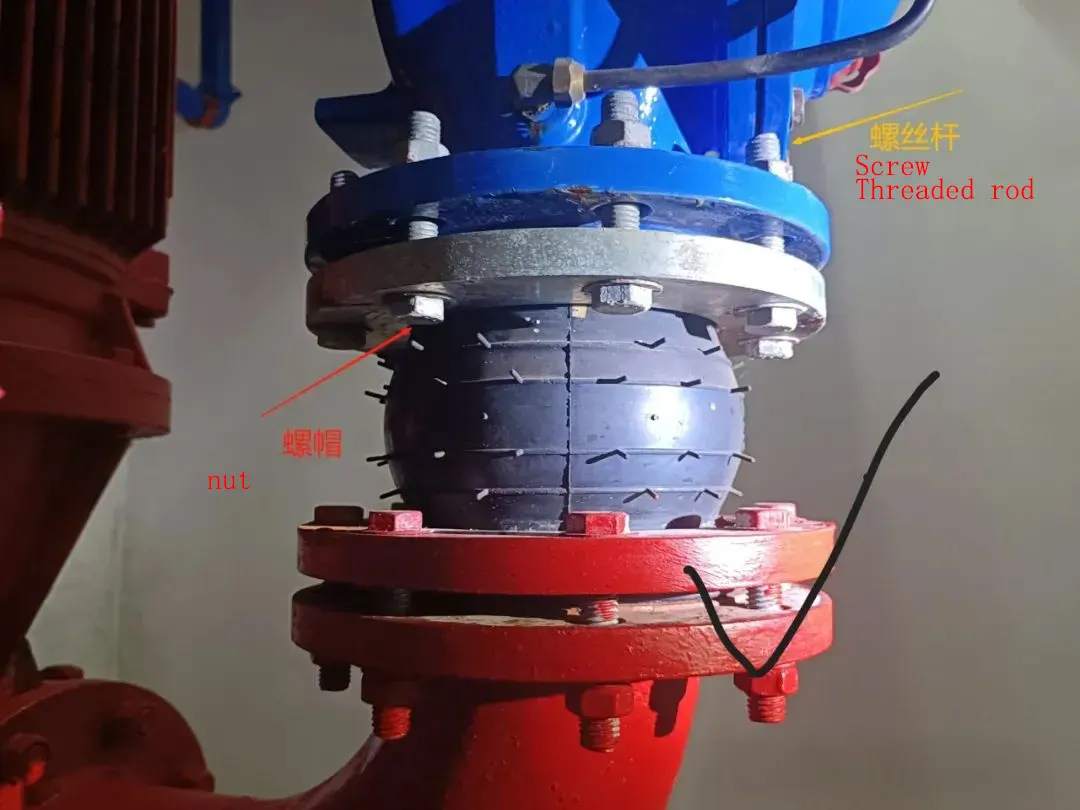

Despite their strength, stainless steel hoses offer a good degree of flexibility—especially those with a corrugated core. This flexibility allows them to handle movement, vibration, and misalignment in piping systems. They can be used in various applications where flexibility is crucial, such as in machinery, HVAC systems, and other industrial setups.

Key Applications of Stainless Steel Hoses

Stainless steel hoses find applications across a wide range of industries and settings:

Industrial Applications

In industrial settings, stainless steel hoses are used for chemical transfer, hydraulic lines, steam conveyance, and gas conveyance. Their ability to resist corrosion and handle high temperatures makes them ideal for these demanding applications.

Food and Beverage Industry

The non-toxic and hygienic properties of stainless steel hoses make them perfect for the food and beverage industry. They ensure the safe and clean transfer of liquids and gases, meeting the stringent hygiene requirements of this sector.

Pharmaceutical and Medical Applications

In the pharmaceutical and medical fields, stainless steel hoses are used to ensure sterility and resistance to chemical attack. These hoses are easy to clean and maintain, critical for maintaining the highest standards of hygiene and safety.

Construction and Marine Applications

Stainless steel hoses are also used in construction for high-pressure hydraulic lines in heavy machinery and concrete pumping. In marine environments, they resist saltwater corrosion, making them suitable for cooling and fuel systems.

Residential Use

Even in residential settings, stainless steel hoses are becoming popular. Kink-free stainless steel garden hoses offer superior durability and flexibility compared to traditional rubber or PVC hoses, making them a long-lasting and reliable choice.

Types of Stainless Steel Hose Fittings

The performance of a stainless steel hose is heavily dependent on the type of fittings used. Several types of fittings are commonly used with stainless steel hoses:

- O-Ring Fittings: Ideal for high-pressure seals, ensuring a leak-free connection.

- JIC Hydraulic Fittings: Widely used in hydraulic systems for their robust and reliable connections.

- Crimp Fittings: Provide a secure and high-strength attachment, often used with braided hoses.

- Barb and Push-On Fittings: Suitable for low-pressure applications, offering a quick and easy assembly.

Choosing the Right Stainless Steel Hose

Selecting the appropriate stainless steel hose requires considering several factors:

- The application: Determine the specific requirements of your application, including the fluids or gases being conveyed, the operating pressure, and the temperature range.

- Material grade: Choose the correct grade of stainless steel (304, 316, etc.) based on the level of corrosion resistance required.

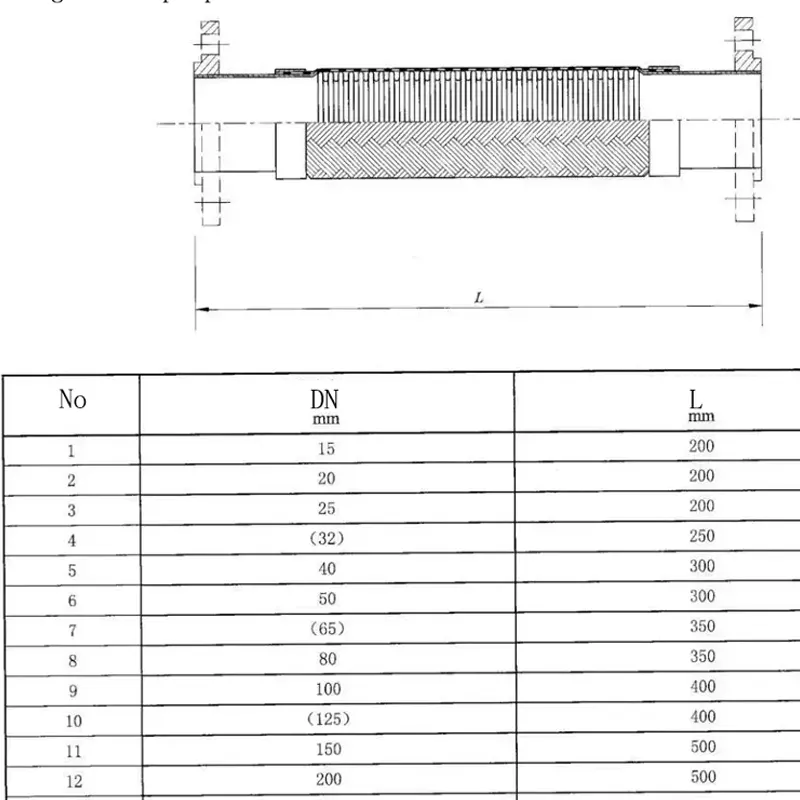

- Hose construction: Consider the core type (corrugated or smooth bore) and the presence of a braid for added strength and flexibility.

- Fittings: Select the appropriate fittings based on the pressure, fluid compatibility, and ease of installation.

Conclusion

In conclusion, stainless steel hoses are undoubtedly a superior choice in many applications. Their exceptional corrosion resistance, high-temperature and pressure tolerance, durability, and flexibility make them a reliable and cost-effective solution for a wide range of industries and uses. If you are looking for a hose that offers long-lasting performance and safety, a stainless steel hose is an excellent investment.

Internal & External Links

Internal Links

External Links

- Link to a reputable stainless steel hose manufacturer

- Link to an industry resource on hose applications