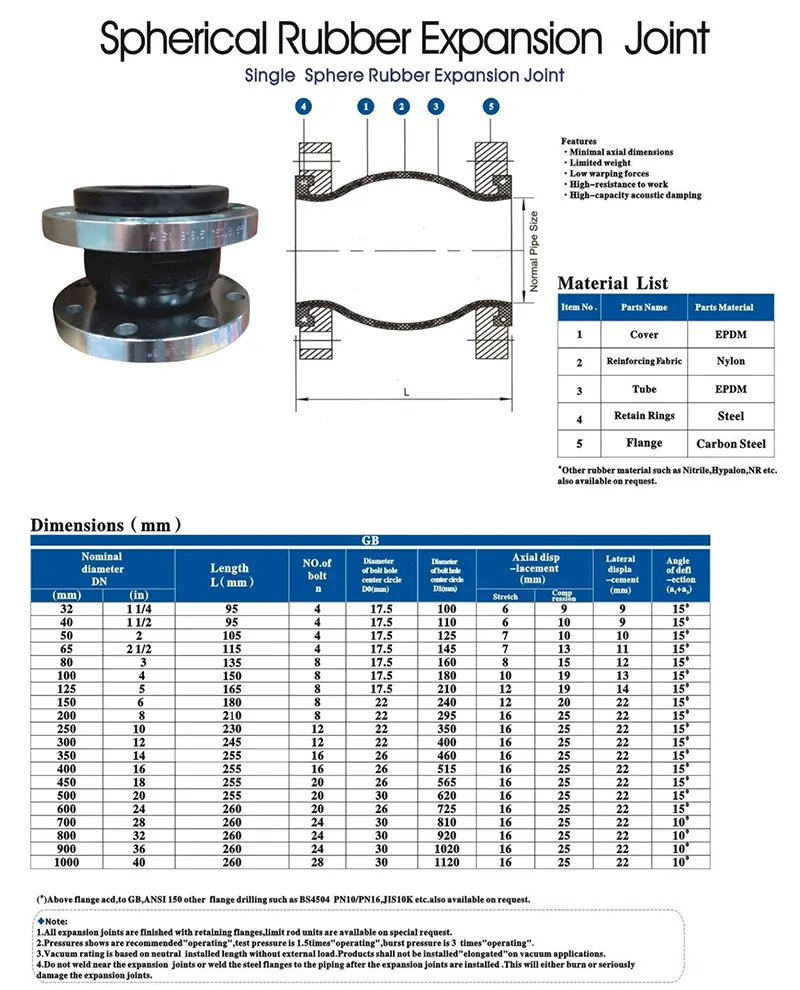

Flange rubber expansion bellows Single Sphere

DN32-DN1200 Flange rubber expansion bellows Factory Wholesale Price

The flange rubber expansion joints are available in sizes ranging from DN32 to DN1200. The rubber materials available include EPDM, neoprene, butyl rubber, nitrile rubber, PTFE, and others. Customization services are also offered. The flange materials include cast iron, carbon steel, and stainless steel, and they are compatible with various flange standards such as ANSI, DIN, JIS, etc.

- Corrosion Resistance: Suitable for various media, resistant to acids, alkalis, and oils.

- High Pressure Resistance: Capable of withstanding high pressure

- Good Elasticity: Effectively absorbs vibration and displacement.

- Easy Installation: Threaded connection facilitates installation and maintenance.

Advantage of Flange Rubber Expansion Bellows

Quality First

Flange Rubber Expansion Bellows for Water and Wastewater

Flange Rubber Expansion Bellows for Water and Wastewater are flexible connectors designed for water and wastewater systems. Made from durable rubber with flanged ends, they absorb vibrations, compensate for pipe movements, and resist corrosion and abrasion. Ideal for clean water and wastewater applications, they ensure reliable, leak-proof performance in demanding environments.

- Superior Flexibility

- Excellent Sealing

- Corrosion and Abrasion Resistance

- Easy Installation

- Durable and Long-Lasting

Quality First

Flange Rubber Expansion Bellows for Power Generation

Flange Rubber Expansion Bellows for Power Generation are essential components designed to handle the demanding conditions of power generation systems. Constructed from high-quality rubber with flanged ends, they absorb vibrations, compensate for thermal expansion, and resist high temperatures and pressure. These bellows ensure reliable performance.

- Vibration Absorption

- Thermal Expansion Compensation

- High Temperature and Pressure Resistance

Quality First

Flange Rubber Expansion Bellows for HVAC Systems

Flange Rubber Expansion Bellows for HVAC Systems are flexible connectors designed to enhance the efficiency and reliability of heating, ventilation, and air conditioning systems. Made from durable rubber with flanged ends, they absorb vibrations, compensate for thermal expansion, and reduce noise transmission. These bellows are ideal for maintaining system integrity, ensuring smooth operation, and extending the lifespan of HVAC infrastructure

- Noise Reduction

- Absorb Vibration

- Durable and Resilient

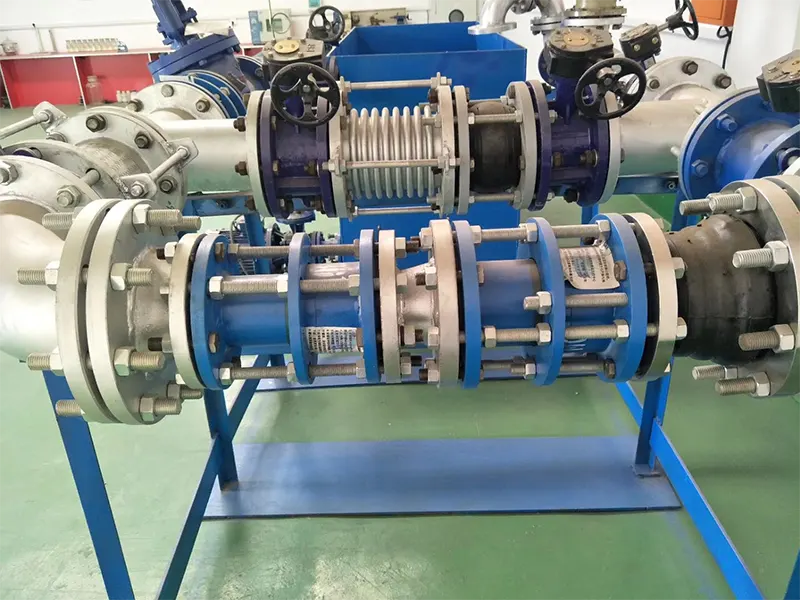

More About Flange Rubber Expansion bellow Joint

What is a Rubber Expansion Joint?

A rubber expansion joint is a flexible component designed to absorb movement in piping systems. It consists of multiple layers of rubber that are reinforced with fabric or metal, allowing it to expand, contract, and shift as needed without damaging the system. These joints play a critical role in protecting pipes, valves, and other components by reducing the stress caused by thermal expansion, vibrations, and other forms of movement.

Why Use a Rubber Expansion Joint?

Rubber expansion joints are commonly used for their ability to:

- Absorb movement: These joints help manage thermal expansion and contraction in pipes, absorbing axial, lateral, and angular displacements.

- Reduce noise and vibration: The flexible rubber material dampens vibrations and reduces operational noise, enhancing the system’s overall performance.

- Increase system longevity: By absorbing shock and vibration, they reduce wear and tear on pipes, helping extend the lifespan of your piping system.

- Compensate for misalignment: Rubber expansion joints are ideal for compensating minor misalignments between connected pipes or other components, ensuring that the system continues to function smoothly.

Industry Applications

Rubber expansion joints are used in various industries, including:

- HVAC systems: They help maintain airflow integrity by absorbing movement in air ducts and piping.

- Water treatment plants: These joints are critical in handling the pressure fluctuations and vibrations in water and wastewater pipelines.

- Chemical processing: In corrosive environments, rubber expansion joints provide the necessary flexibility to withstand temperature changes and chemical reactions.

- Power generation: They are often found in the cooling systems of power plants, where thermal expansion is a concern.

- Oil and gas: Rubber expansion joints help minimize pipeline stresses in oil and gas refineries.

There are several types of rubber expansion joints, each suited to different applications:

- Single Sphere: Typically used in low-pressure applications, ideal for absorbing axial movements.

- Double Sphere: These are designed for larger movements and are typically used in systems where more flexibility is required.

- Convolutioned: These have an accordion-like structure, ideal for high-pressure systems and where additional movement capabilities are needed.

- Elbow Type: These are used to absorb angular displacements in pipe elbows.

Do I Need Tie Rods?

Tie rods are used in some rubber expansion joints to prevent over-expansion, ensuring the joint doesn’t exceed its design limits under pressure. While not always necessary, tie rods are recommended for high-pressure systems where there’s a risk of excessive movement. They help stabilize the joint and maintain its performance over time.

Do I Need a Vacuum Ring?

A vacuum ring is used in rubber expansion joints to prevent the joint from collapsing under negative pressure conditions. If your piping system is exposed to vacuum or suction conditions, it’s highly recommended to install a vacuum ring. It adds support to the expansion joint and ensures it can handle the internal vacuum without failure.

Get A Quote !