Who is this for? Buyers, equipment engineers, maintenance teams

Goal: Understand what a flexible stainless-steel hose consists of, how to select it, and how to avoid failures—so you can brief suppliers in one go.

TL;DR

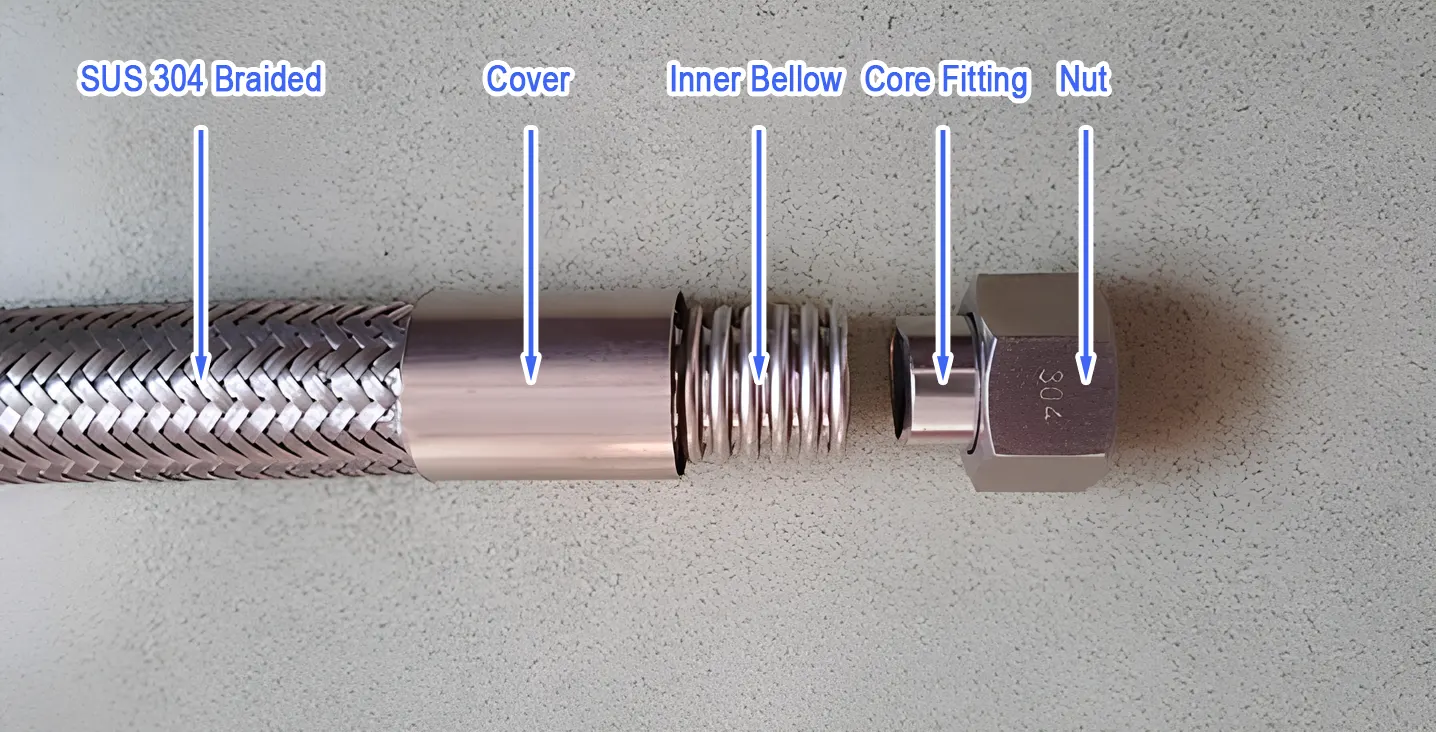

A typical flexible stainless-steel hose has four key parts:

- Corrugated inner core – provides flexibility and absorbs movement.

- Braided reinforcement layer (single/double/multi) – carries pressure and impact.

- Ferrule / braid collar – mechanically locks the braid to the fitting and enables full-penetration welding.

- End fittings (NPT/BSP/Flanges/Camlock/Tri-Clamp) – connect to your system and define the sealing method.

Send these 8 parameters for a fast quotation: medium, temperature, pressure/vacuum & pulsation, flow/pressure-drop (optional), minimum bend radius, connection standard, end-to-end length & tolerance, environment.

What Does It Consist Of?

1) Corrugated Inner Core

- Function: Flexibility, vibration damping, thermal expansion compensation.

- Materials: AISI 304/316L (choose 316L for chloride/corrosive environments).

- Geometries: Annular (higher pressure & fatigue life) or helical (easier to form/clean).

- Optional liners: PTFE liner for low friction, broad chemical compatibility, and hygienic service; smooth bore sleeves to reduce turbulence.

2) Stainless-Steel Braid (Reinforcement)

- Function: Takes internal pressure and limits radial growth of the core.

- Layers: Single for medium pressure; double/multi-layer for high pressure or frequent pulsation.

- Material: 304/316 (prefer 316 for marine/salt-spray).

- Tip: For water hammer/frequent starts, choose a denser weave or double braid.

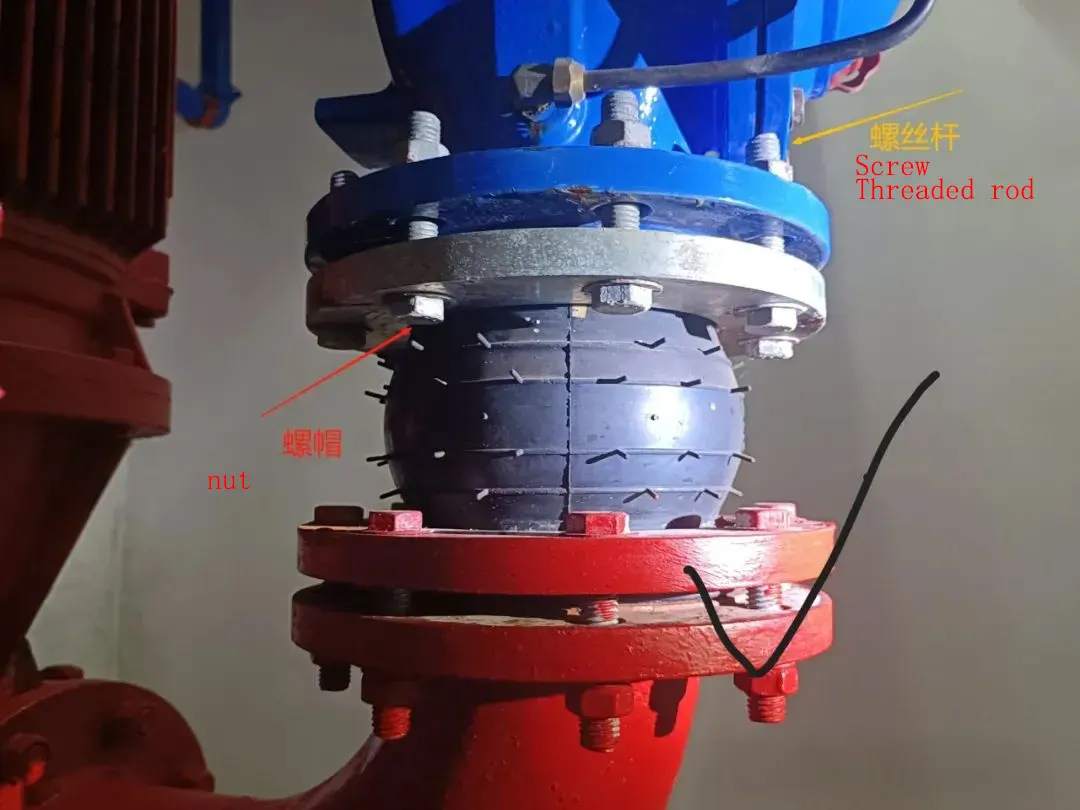

3) Ferrule / Braid Collar

- Function: Securely locks the braid to the fitting; critical for pressure rating and service life.

- Build: Crimped or sleeve-type; high-end hoses use hydroforming + GTAW/TIG full-circumference welds.

4) End Fittings

- Threads: NPT, BSPP/BSPT, Metric.

- Flanges: ASME/ANSI, DIN/EN, JIS.

- Quick-connect / Hygienic: Camlock, Tri-Clamp.

- Seals: Metal-to-metal, O-ring, cone seal, or gasket—match medium and temperature.

Rule of thumb: For high-temperature steam use flanged ends + spiral-wound gasket; for frequent connects use Camlock/TC.

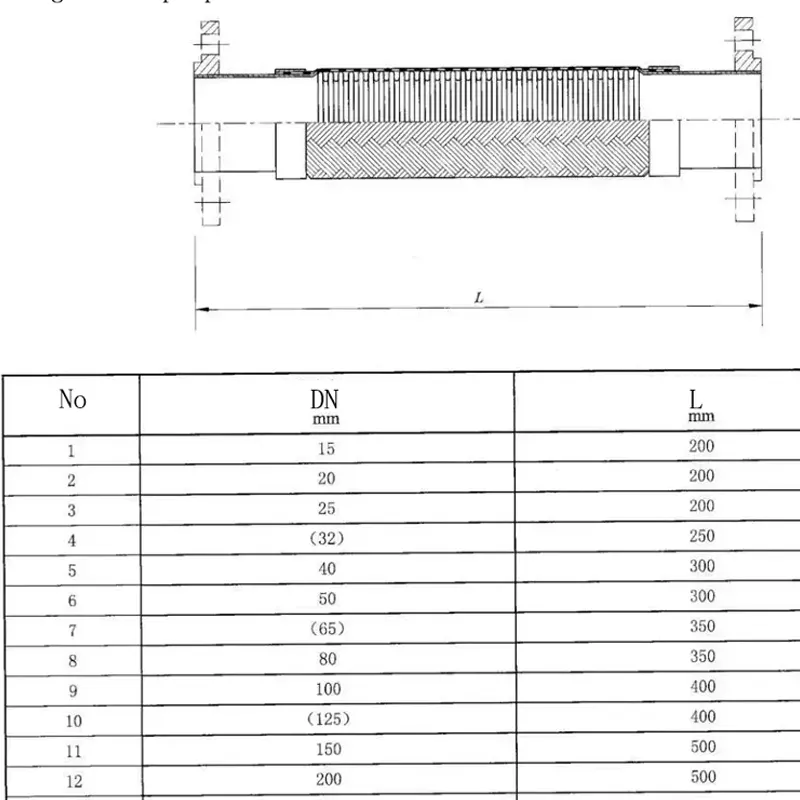

Sizes, Pressure Rating & Bend Radius

Nominal Sizes (Typical)

| DN | Typical ID (mm) | Typical OD (mm) | Common Threads/Flanges |

|---|---|---|---|

| 8 | 8 | 12–14 | 1/4″–3/8″ NPT/BSP |

| 15 | 15 | 20–22 | 1/2″–3/4″ NPT/BSP; DN15 flange |

| 25 | 25 | 32–36 | 1″ NPT/BSP; DN25 flange |

| 40 | 40 | 50–55 | 1½”–2″ thread; DN40/50 flange |

Dimensions vary by manufacturer; use your vendor’s datasheet for final selection.

Pressure Rating

- Depends on core wall thickness & corrugation, braid layer count & density.

- Datasheets list ratings at ~20 °C plus a temperature derating factor (e.g., ×0.6 at 400 °C).

- For pulsation/impact, keep a ≥2× safety factor and consider dampers/accumulators.

Minimum Bend Radius (MBR)

- Static vs dynamic reciprocating MBR differ (dynamic requires a larger radius).

- Radius is measured to the hose centerline.

- Avoid torsion; add swivel joints or orientation marks if needed.

Materials & Media Matching

| Application | Recommended Build | Notes |

|---|---|---|

| Water/Air (general) | 304 braid + 304 core | Cost-effective |

| Chlorides / Marine | 316L core + 316 braid | Pitting-resistant |

| Corrosives / Food & Pharma | PTFE-lined core + 316 fittings | Hygienic, low friction |

| High-temp Steam (≥180 °C) | 316L + flanged ends, metal gasket | Apply temperature derating |

| Vacuum | Annular core + protective cover | Prevents collapse; add vacuum support if needed |

Selection Checklist (copy & send to supplier)

- Medium (name, corrosivity, hygienic requirement)

- Temperature range (normal/peak/duration)

- Pressure (normal/max, pulsation? vacuum?)

- Flow / ΔP target (optional)

- Minimum bend radius & motion profile (static/dynamic; any torsion?)

- Connections (NPT/BSP/flange standard/quick-connect model)

- End-to-end length (with tolerance)

- Environment (outdoor/salt-spray/cleaners; need guard sleeve?)

- Standards/verification (e.g., ISO 10380, MTRs, hydrotest report)

Standards & Compliance

- ISO 10380 (metallic hose): type tests, cyclical life, pressure & bend testing.

- Also consider EN/DIN/ASME for flanges/materials/welding.

- Hygienic service: FDA, EU 10/2011 (for PTFE liners & seals).

Installation Essentials & Common Failures

7 Golden Rules

- No torsion: add orientation marks; use swivels if needed.

- Reserve bend: install with 1.2–1.5× MBR margin—don’t stretch straight.

- Use for misalignment—not as an expansion joint.

- Support & guide: long/vertical runs need hangers to avoid self-weight tension.

- Protect from heat/abrasion: guards and bend restrictors.

- Control water hammer: soft-start valves, accumulators, pulsation dampers.

- Weld quality: full