Reliable and Durable Solutions for Vibration Absorption, Pressure Relief, and System Longevity in Pump and Piping Applications.

Based on design drawings and technical specifications, use cutting equipment (such as laser cutters, plasma cutters, or sawing machines) to cut metal sheets or tubes into the required dimensions and shapes. Ensure cutting precision, avoid burrs or deformation, and lay a solid foundation for subsequent processing.

Form metal strips into tubular shapes using extrusion equipment. This process typically involves high-frequency welding or cold rolling to ensure the tube’s roundness, uniform wall thickness, and weld quality, providing qualified raw materials for subsequent corrugated pipe forming.

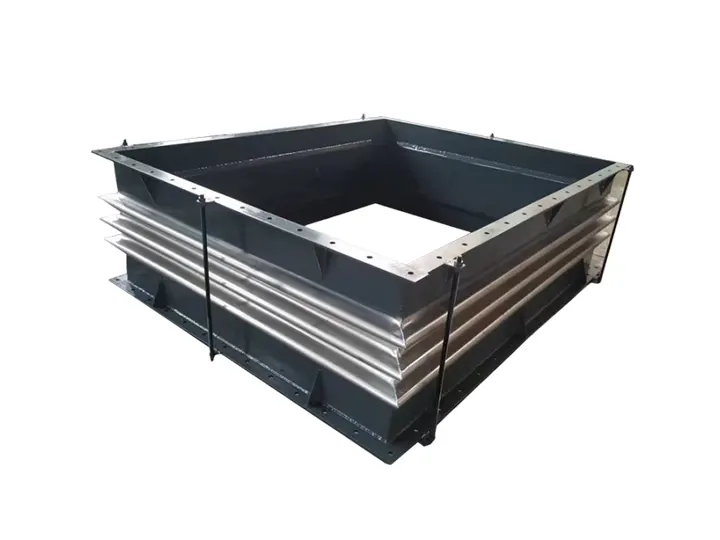

Use hydraulic or mechanical forming equipment to extrude steel tubes into corrugated pipe blanks. The corrugated design must meet the expansion and compensation performance requirements of the compensator, while ensuring uniformity and strength of the corrugations.

Cut the corrugated pipe blanks into specific lengths according to design requirements. Ensure smooth cuts, avoid deformation or burrs, and facilitate smooth progress in subsequent welding and assembly processes.

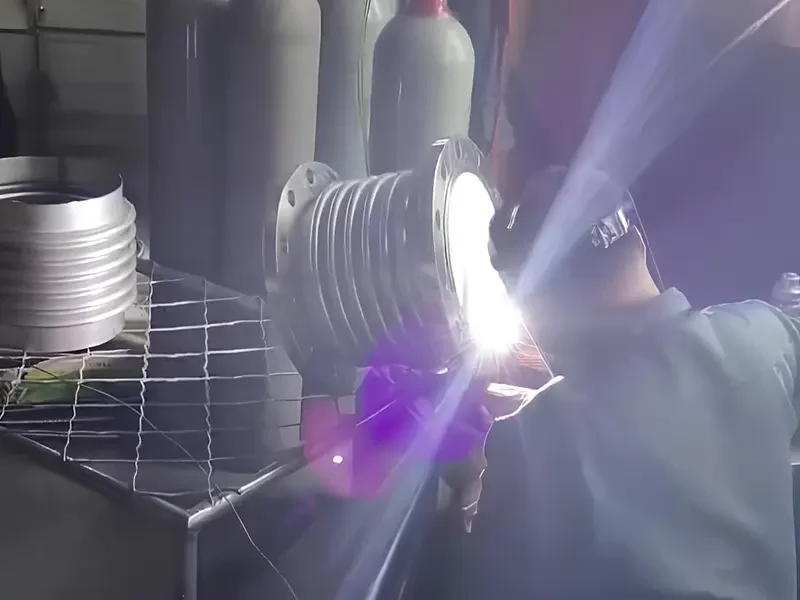

Weld flanges, connectors, and other fittings to the corrugated pipe sections. Use welding techniques such as TIG welding or arc welding to ensure strong, leak-proof welds that comply with pressure vessel or pipeline standards.

Conduct comprehensive quality inspections on the finished product, including dimensional checks, pressure tests (hydrostatic or pneumatic), and non-destructive testing (such as ultrasonic or radiographic testing). Ensure the compensator’s strength, sealing performance, and overall compliance with design requirements and industry standards, guaranteeing safe usage.

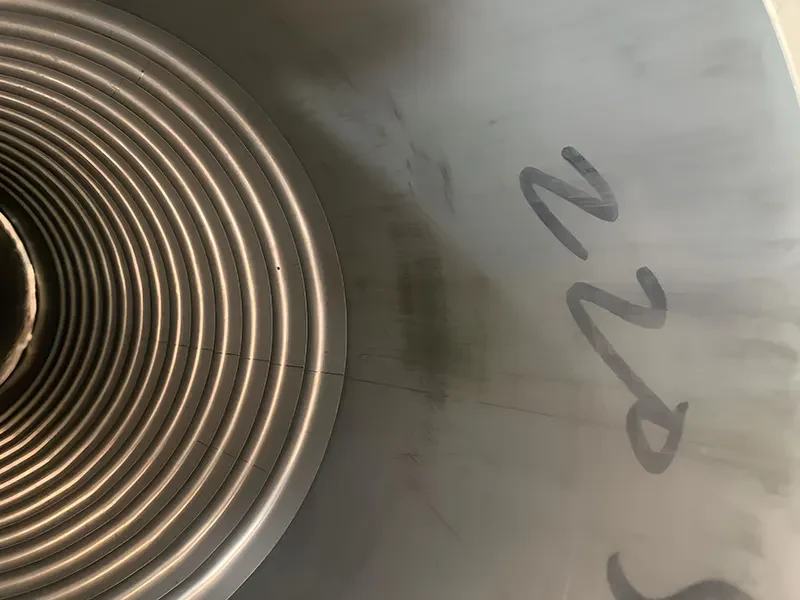

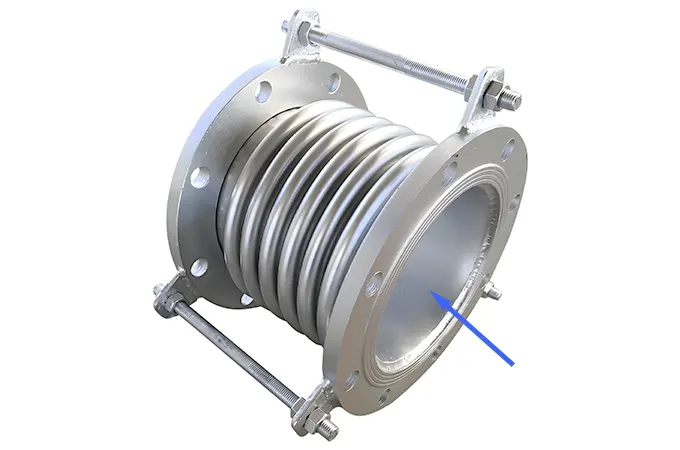

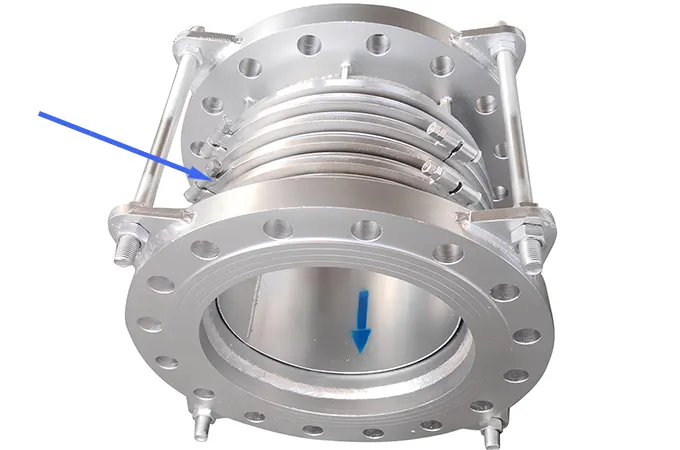

The metal bellows compensator absorbs pipeline dimensional changes caused by thermal expansion and contraction through the bellows. One end of the internal sleeve is welded and fixed to the bellows, while the other end is not welded. If both ends are welded, the bellows will lose its compensating capability.

The primary purpose of the sleeve is to ensure the smooth delivery of the medium and to prevent turbulence in the bellows. If the internal sleeve has no weld seams and the fluid flows in one direction, the fluid will enter the bellows, causing turbulence. The impurities in the fluid will accumulate in the bellows, affecting both fluid transport and the normal operation of the bellows. In vertical pipelines, if there are no weld seams, impurities in the fluid are more likely to accumulate in the bellows. Therefore, the welded end should be installed at the water inflow end of horizontal pipelines and at the top end of vertical pipelines.

SUS304/316/321 or customized

The metal bellows compensators manufactured by our company are made from austenitic stainless steel (0Cr19Ni9, 1Cr18Ni9Ti). When the connecting pipe and flange materials are carbon steel, the product’s working temperature range is -20℃ to 400℃. When both the connecting pipe and flange are made of stainless steel, the working temperature range is -250℃ to 600℃. With the addition of a temperature-resistant lining, the product can withstand temperatures above 800℃ to 1200℃. We can also manufacture custom compensators using other metals and fiber materials according to the user’s requirements.

Ultra-High Pressure Flanged Bellows Compensator

Our PTFE metal bellows compensators are specifically designed for pipeline systems handling highly corrosive media. In addition to absorbing vibration and compensating for displacement, the compensator is enhanced with a PTFE inner sleeve, which improves corrosion resistance to various concentrations of acids, alkalis, salts, and other corrosive substances. These products are widely used in pipeline systems across industries such as chemicals, petroleum, power, and pharmaceuticals, particularly in systems with high demands for corrosion resistance and pressure endurance.

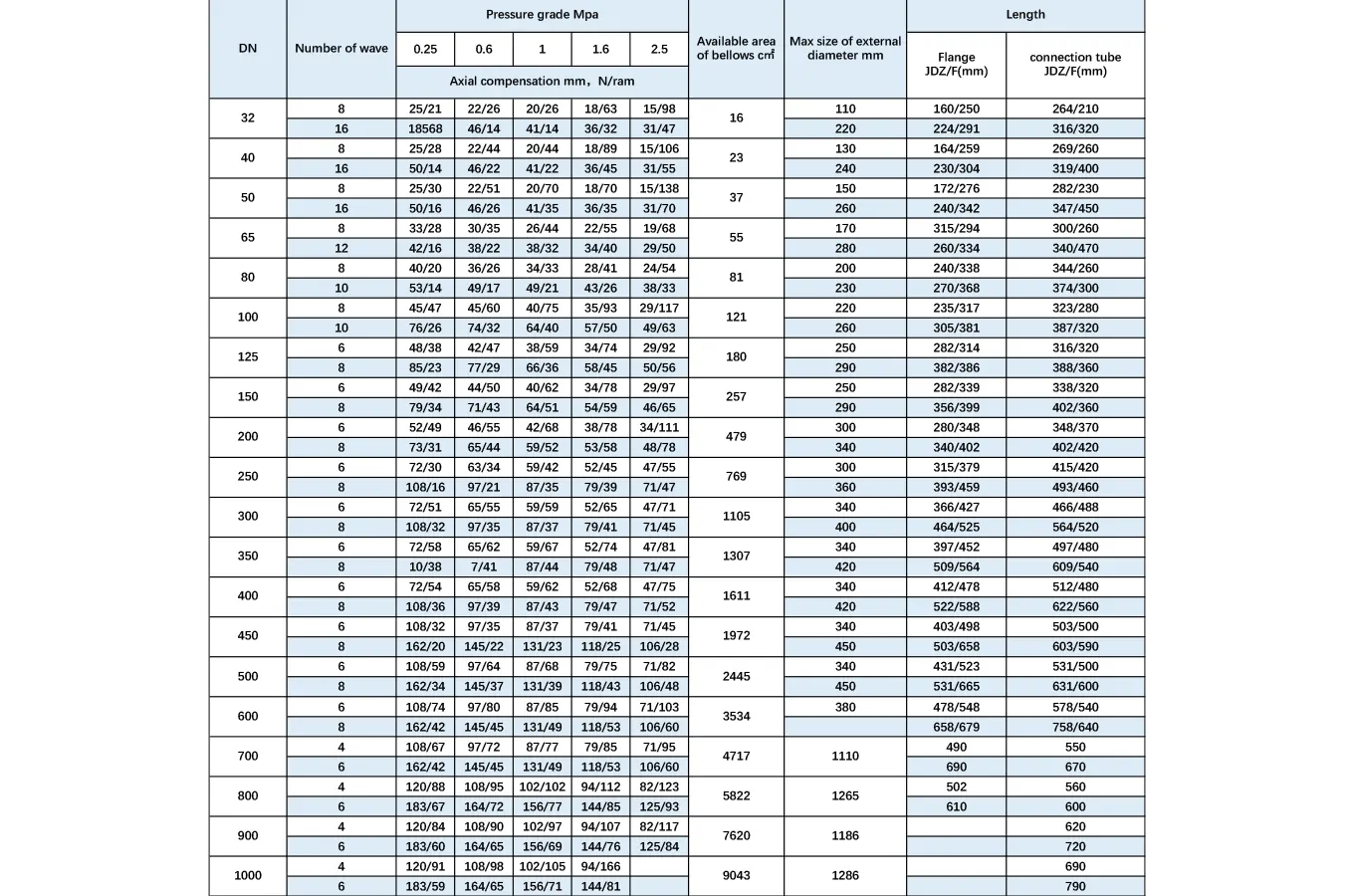

Metal compensators are customized according to requirements. Please provide the dimensions, length, working temperature, medium, and other operating conditions for the bellows compensator. It would be even better if you have drawings available.

Our standard sizes for metal compensators range from DN25 to DN1000. Of course, we can also manufacture larger diameters based on the provided drawings.

Sample Subtitle

Our metal expansion joints have obtained ISO9001 certification.

Our metal expansion joints can issue MTC reports.

In addition, if you need From E or CO certificate, we can also provide it.

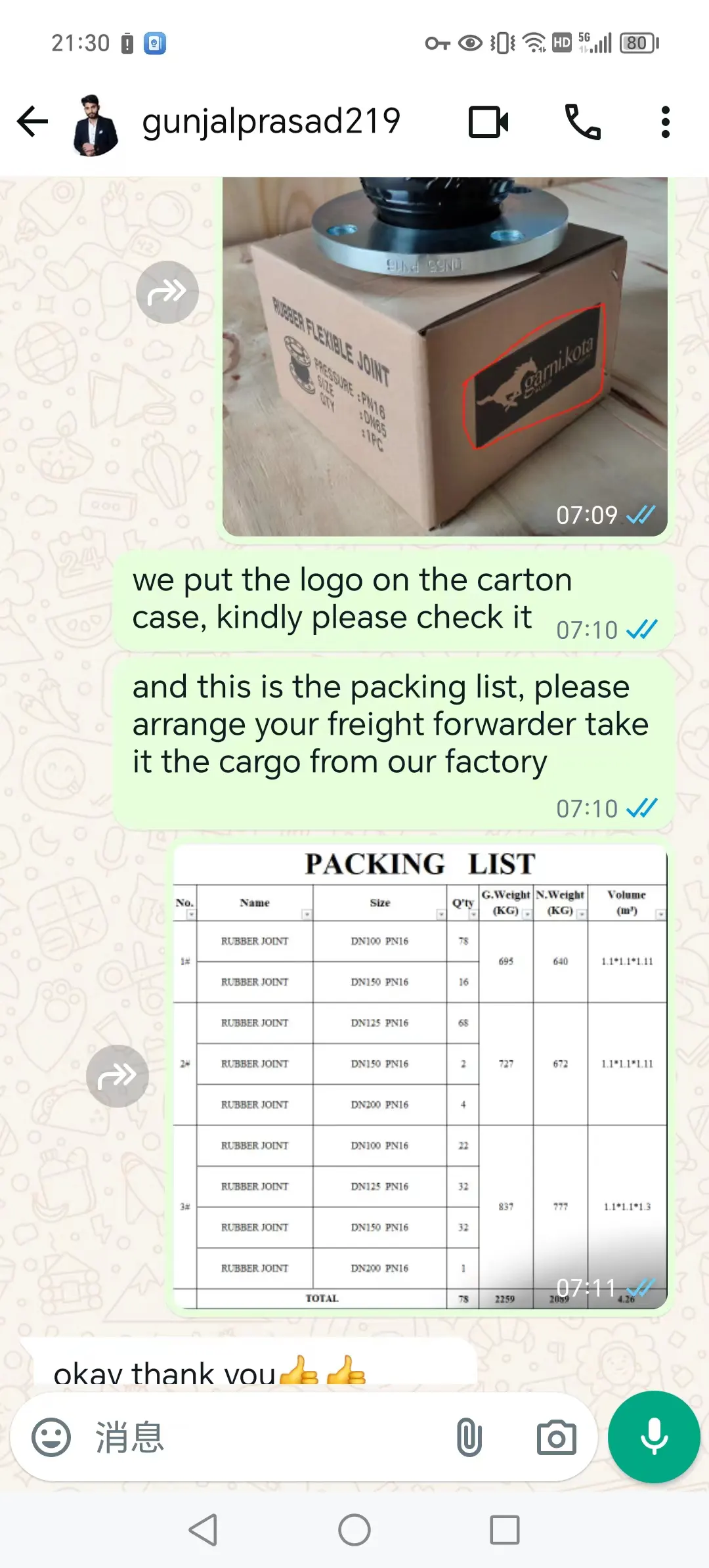

Our customers appreciate our clear communication and professional support. Before the sale, we carefully confirm project details such as media, temperature, pressure, size, installation length, and more. During the sale, we provide professional installation guidance videos to ensure smooth installation, efficient production, and on-time delivery. After the sale, we provide reliable warranty services for our products to give you peace of mind. With real-time updates and after-sales assistance, we make it easy and reliable to work with us, helping you focus on growing your pipeline safety business.

Got questions about our products or services? Our FAQ section provides quick and clear answers to common queries. Dive in to learn more about HuiXiang Steel Co., Ltd. and how we can serve your steel needs.

Foshan Caijie Technology Company specializes in metal bellows expansion joints for over 10 years, delivering high-quality pipeline solutions. Our advantages:

Before starting to use our services, please fill in the following form to let us know which type of stainless steel duct system you want to import from China.

WhatsApp us

Choose Caijie

Stretch Your Budget, Not Your Standards !

Before starting to use our services, please fill in the following form to let us know which type of stainless steel duct system you want to import from China.

Once we receive the detailed information regarding your request, your assigned customer representative will contact you shortly.

If you need help, please email us at sales1@caijie-tech.com.