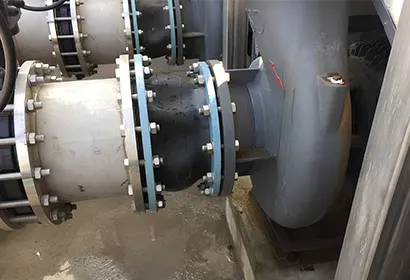

Our rubber joints can protect your equipment from various pressure sources while being cost-effective and durable, extending the lifespan of your piping system. We specialize in providing rubber joints for pumps and pipeline equipment, which can absorb vibrations, stretch, and expand, ensuring smooth operation of the pipeline system.

Reliable and Durable Solutions for Vibration Absorption, Pressure Relief, and System Longevity in Pump and Piping Applications.

Rubber Expansion Joint Union Thread

Rubber Expansion Joint Doube Sphere

Rubber Expansion Joint Eccentric reducing

Rubber Expansion Joint Full sealed

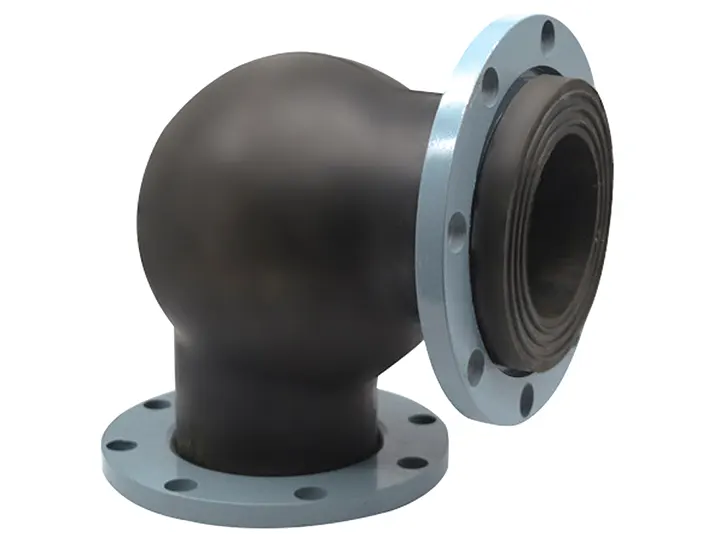

Rubber Expansion Joint Elbow

Rubber Expansion Joint PTFE Sleeve

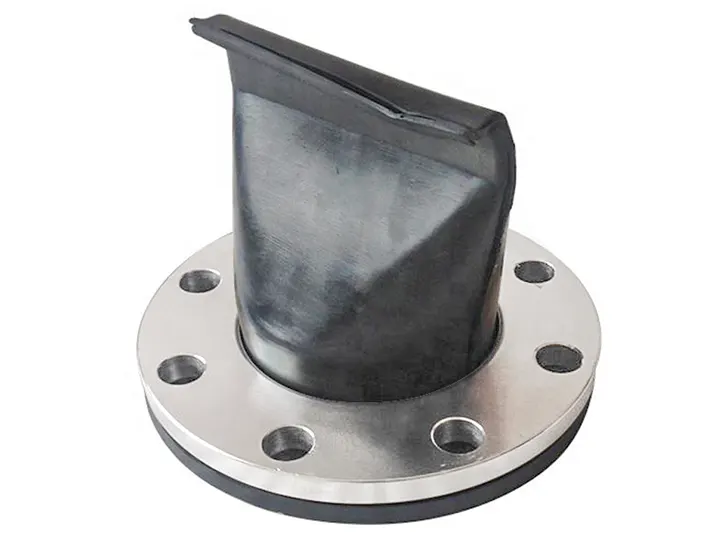

Rubber Expansion Joint Duckbill check valve

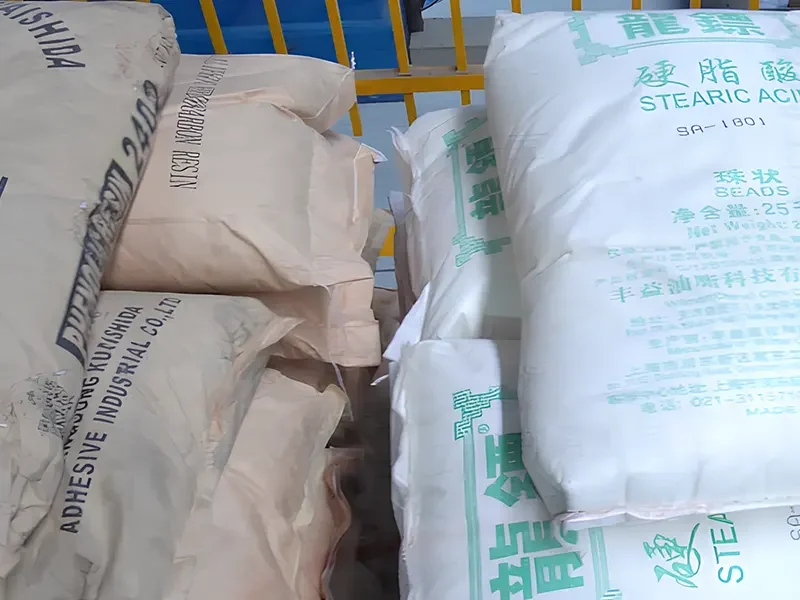

Using high-quality rubber raw materials

We purchase high-quality rubber raw materials from high-quality raw material suppliers and control the quality from the source.

Factory independent rubber refining

Our factory has its own rubber refining equipment, which can make different rubber ratios according to customer requirements, and can also control the rubber quality from the source

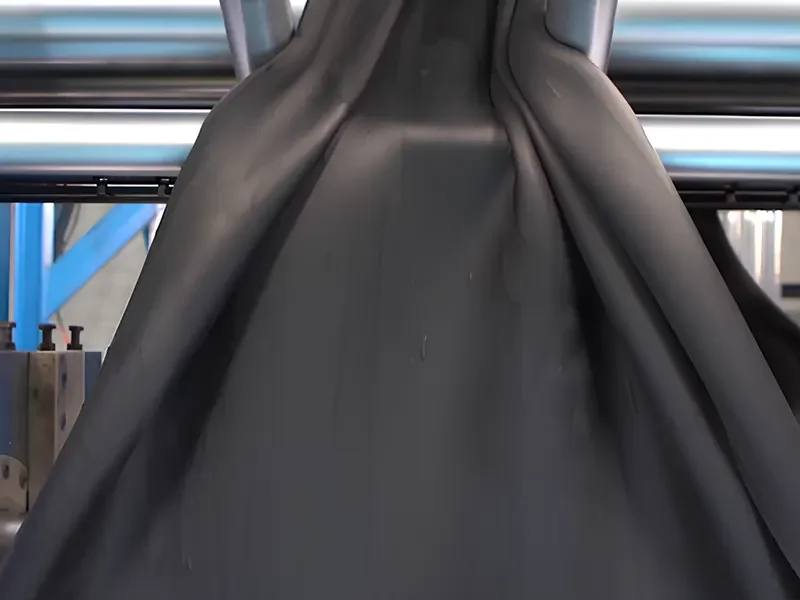

Rubber cutting into slices in each pcs

We have an automatic rubber slicer, which can cut rubber into uniform thickness and size, making it easier to process later.

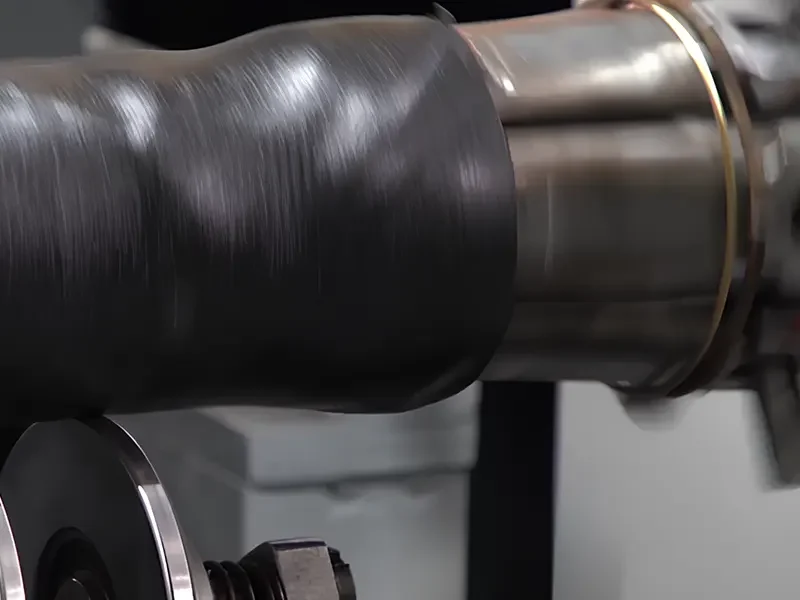

Rubber molding

We use standardized machines to complete the molding of rubber flexible joint blanks

Vulcanization process

We have several professional vulcanization equipment to vulcanize the rubber flexible joint blanks.

Flange processing

We will process flanges according to the material, hole requirements, and flange thickness required by the customer.

Flange installation

We have semi-automatic flange installation equipment that can quickly assemble the rubber joint and flange

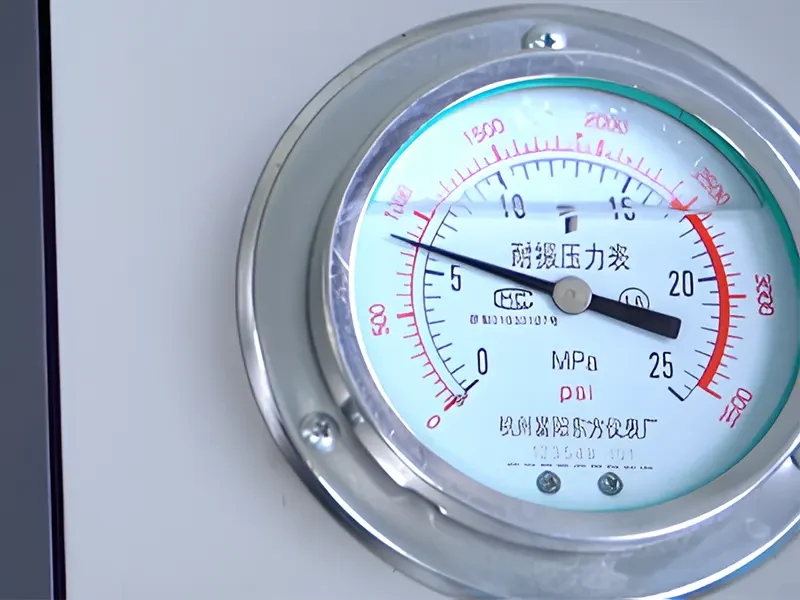

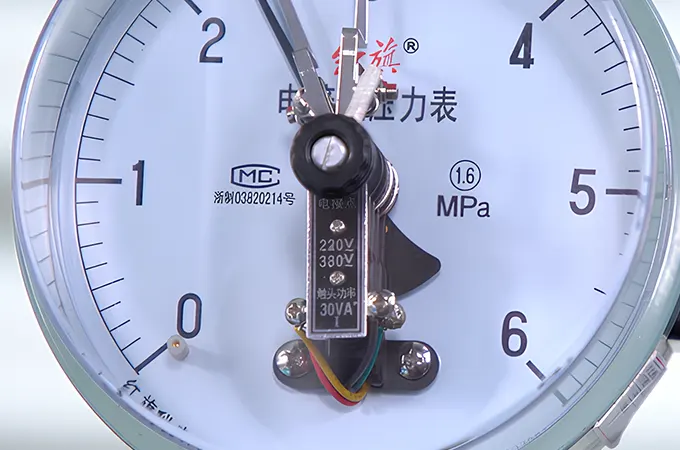

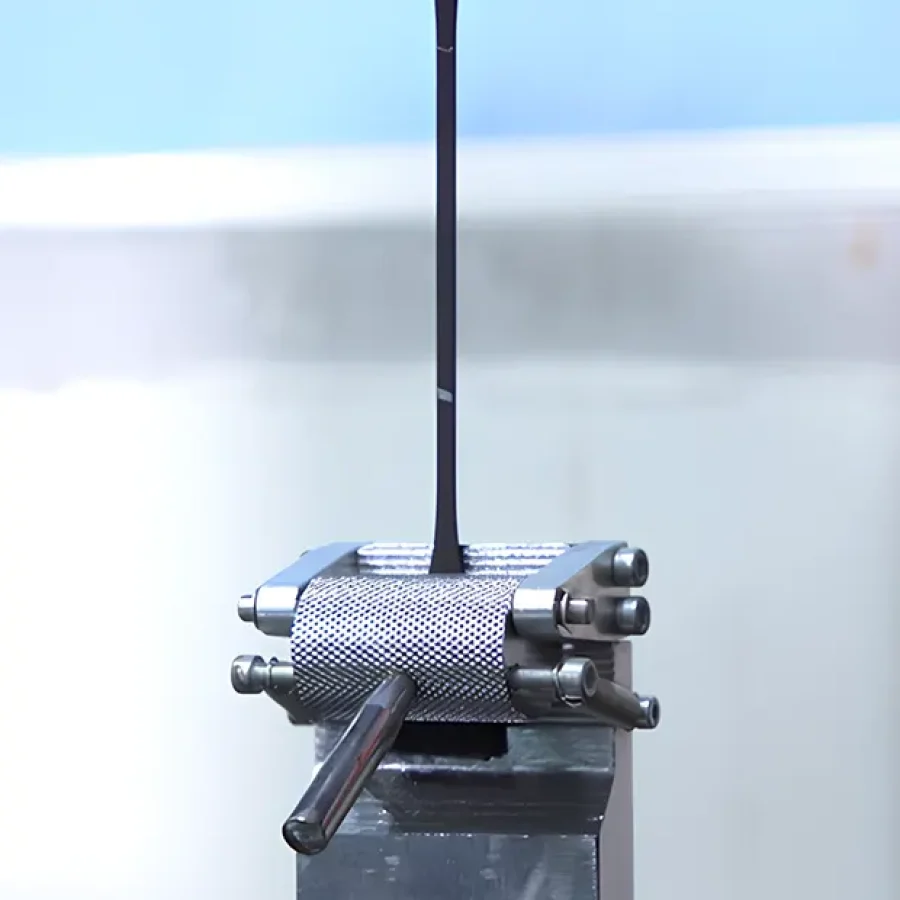

Testing

We can perform pressure tests, vibration tests and other tests according to customer requirements and issue test reports

Packing and Shipping

We will fully seal and pack each rubber joint. We can provide carton packaging if the customer requires. The carton can be printed with a logo.

Our rubber joints are made from first-hand rubber raw materials, not second-hand materials. Additionally, our rubber joints use high-quality natural rubber, not low-quality alternatives. Furthermore, our rubber content exceeds 80%, while many manufacturers lower the rubber content to reduce costs. This aspect cannot be identified by appearance alone.

Our rubber joints have no bubbles, cracks, burrs, or other defects. The surface is smooth and even, without any obvious irregularities or appearance flaws, ensuring good sealing performance and a long service life.

Our rubber joints have high tensile strength, capable of withstanding the tension and compression forces during the operation of equipment. They will not experience issues such as breakage or cracking, ensuring the normal operation of the equipment and production.

Reliable & strong

Our rubber joints feature a structural skeleton layer made of multiple layers of polyester cord fabric, with the connections reinforced by steel rings made of multiple strands of steel wire, effectively preventing detachment.

The situation where the rubber joint needs to be equipped with a negative pressure ring usually occurs in an environment where the pipeline system may have negative pressure. Negative pressure refers to the situation where the air inside the pipeline is sharply reduced due to some reason, forming a suction state. If the rubber joint cannot resist the negative pressure in this case, it may be sucked flat, affecting the normal operation of the pipeline.

Specifically, the following are some application scenarios where negative pressure rings may be required on rubber joints: vacuum pipe systems, where the pressure inside the pipe is lower than atmospheric pressure. Negative pressure areas may be temporarily formed at the inlet and outlet of water pumps, especially when starting or stopping the pump. Certain industrial processes, such as gas discharge or suction operations, may cause the pressure inside the pipe to drop. The function of the negative pressure ring is to protect the rubber ball from being sucked flat when encountering negative pressure, thereby ensuring the normal operation of the pipeline and improving the applicability and safety factor of the rubber joint. When installing the negative pressure ring, the appropriate material should be selected and ensured to be installed correctly to provide additional protection in corrosive pipes.

After conducting an initial 25kg rubber joint burst pressure test, we were surprised to find that it withstood a pressure as high as 8.9 MPa, far exceeding our expectations. In industrial production, the performance of rubber joints often determines the stability and safety of the entire system. Such outstanding performance undoubtedly gives us great confidence in the quality of this rubber joint.

To further understand its performance, we decided to conduct a series of more rigorous tests. Under simulated extreme conditions, the rubber joint not only demonstrated excellent compression resistance but also exhibited good elasticity and wear resistance. Even under prolonged high-load operation, it was able to maintain stable performance without any noticeable signs of aging or damage.

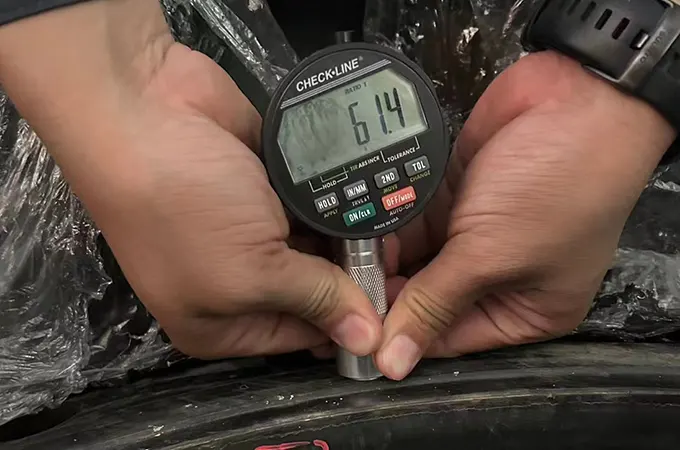

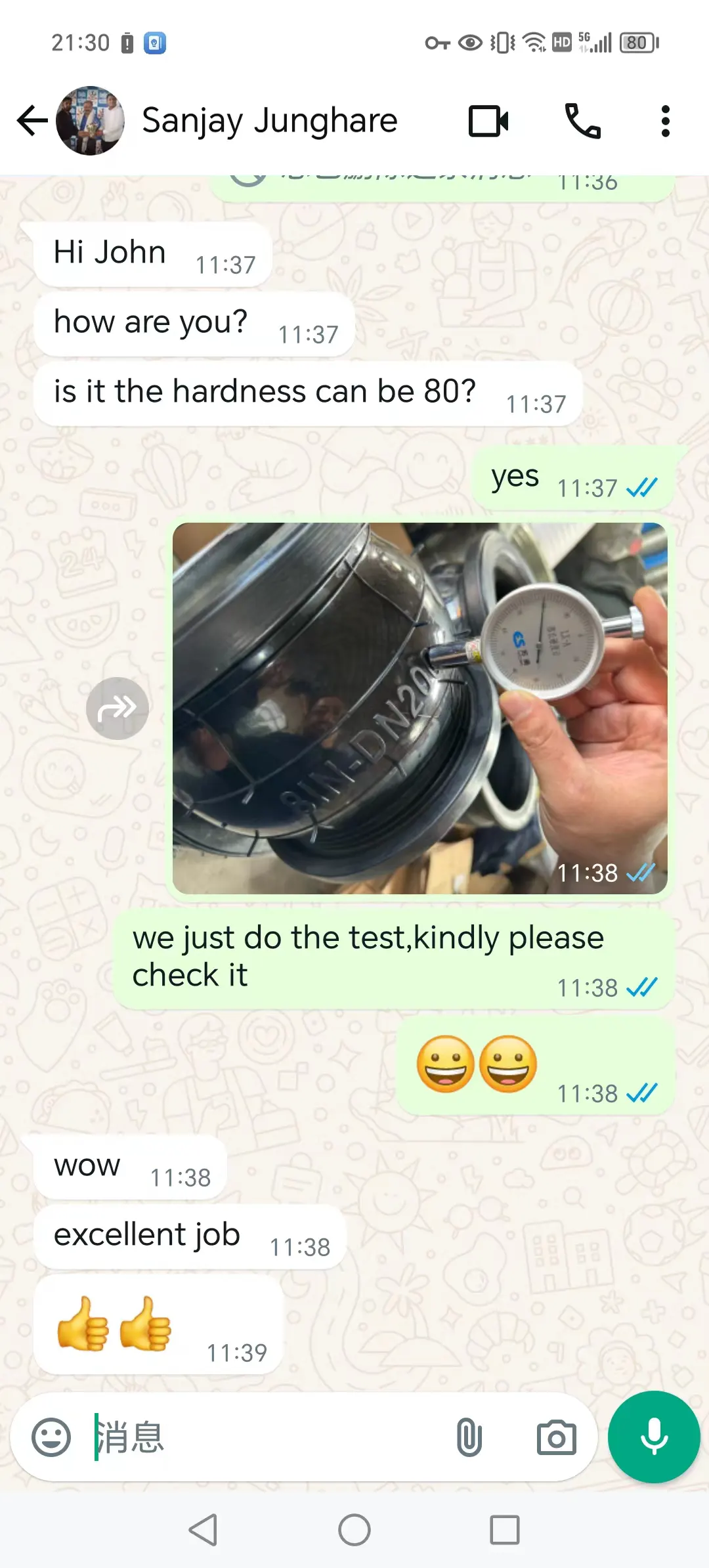

The hardness of a rubber joint refers to its compression resistance, typically measured using a durometer. A good rubber joint should have an appropriate hardness, neither too hard nor too soft. If the rubber joint is too hard, it will be difficult to bend and connect during installation, potentially causing damage. On the other hand, if the rubber joint is too soft, it may become deformed, aged, or cracked during use, affecting its lifespan and sealing performance.

The rubber joints in our factory are made with our own rubber compound formulations. The standard rubber hardness is around 60, and our hardest ones can reach approximately 80.

The tensile strength of a rubber joint refers to its ability to resist stretching, typically measured through a tensile test. A good rubber joint should have a high tensile strength, capable of withstanding the tension and compression forces during the operation of equipment. If the tensile strength of the rubber joint is insufficient, it may easily break or crack, which would affect the normal operation of the equipment and production.

Every batch of rubber raw materials for our rubber expansion joints undergoes tensile strength sampling tests to prevent rubber cracking.

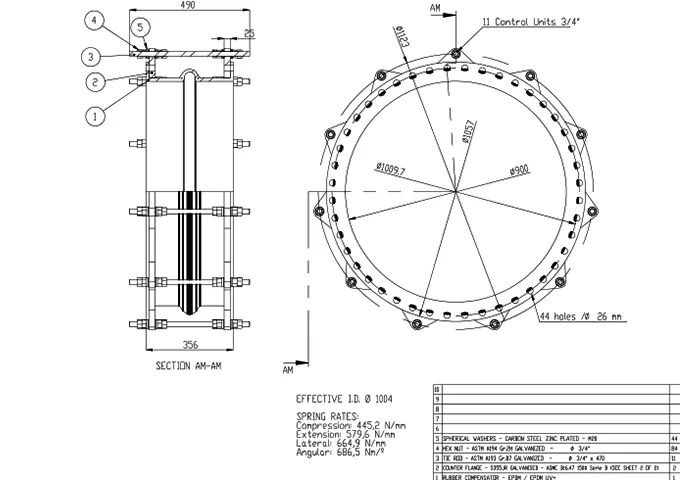

We can provide customized services based on the drawings. For old pipelines, rubber joints often require replacement. If you have the drawings, you can send them to us, and we will produce according to the drawings and assembly requirements. Since molds vary between manufacturers, we can guarantee smooth installation with minimal tolerances, but we cannot ensure that the joints will be exactly identical. For new pipeline applications, the process is much simpler. You only need to provide the pipeline diameter and the required length, and we will quickly ship based on the stock availability of rubber joints.

The following are some common problems with rubber joints. We have listed three examples and given corresponding solutions and prevention measures.

01

Solution:

If there is negative pressure in the pipeline, a negative pressure ring needs to be added

02

Solution:

Replace high-quality rubber flexible joints and refuse to use low-quality and cheap rubber joints.

03

Solution:

The pipeline pressure is too high, resulting in rupture. A PN25 pressure rubber joint should be used.

Sample Subtitle

Our rubber flexible joints have obtained ISO9001 certification and WARS certification.

Our rubber expansion joints can issue MTC reports.

In addition, if you need From E or CO certificate, we can also provide it.

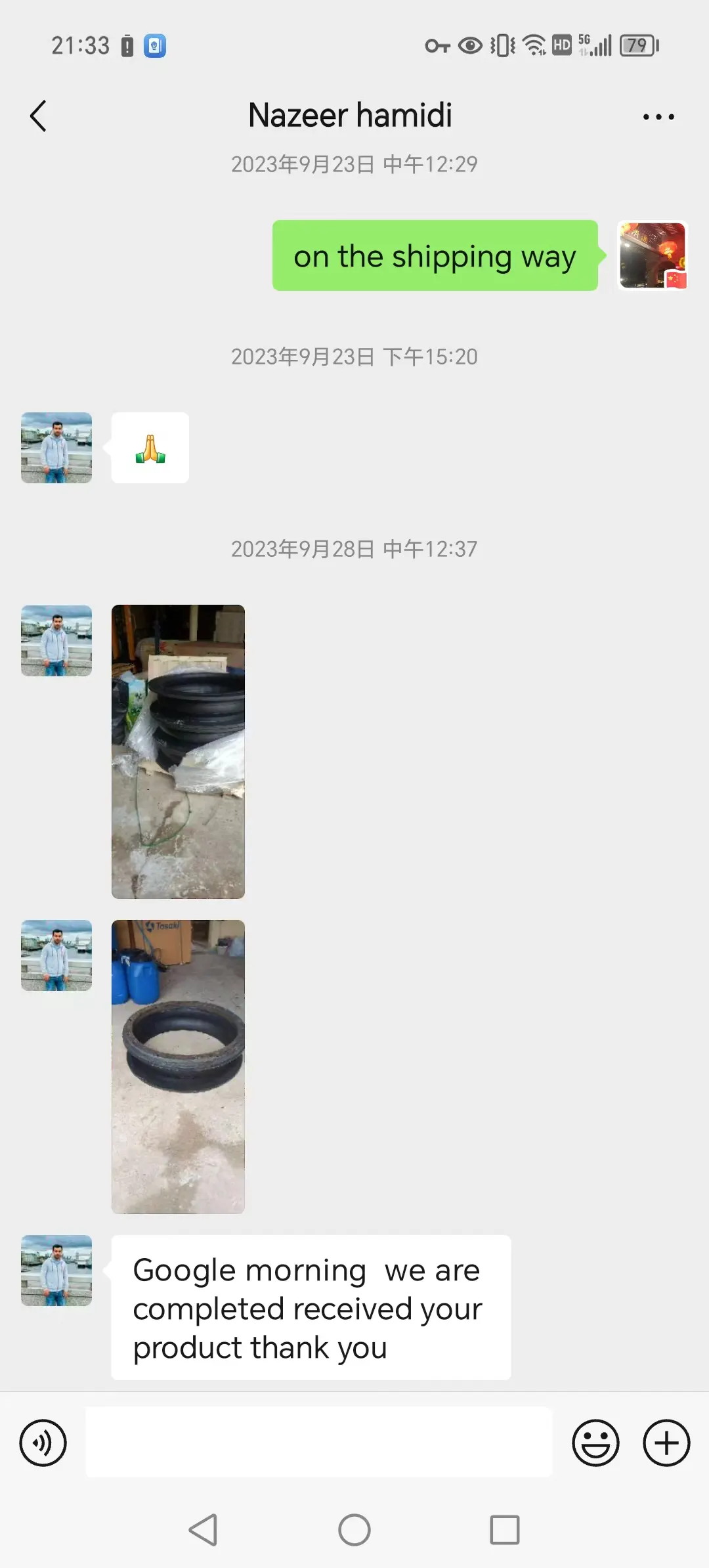

Our customers appreciate our clear communication and professional support. Before the sale, we carefully confirm project details such as media, temperature, pressure, size, installation length, and more. During the sale, we provide professional installation guidance videos to ensure smooth installation, efficient production, and on-time delivery. After the sale, we provide reliable warranty services for our products to give you peace of mind. With real-time updates and after-sales assistance, we make it easy and reliable to work with us, helping you focus on growing your pipeline safety business.

Got questions about our products or services? Our FAQ section provides quick and clear answers to common queries. Dive in to learn more about rubber virbation bellow expansion joint. and how we can serve your needs.

We specialize in application and design, dedicated to helping our customers identify the most cost-effective solutions. Our engineering and manufacturing teams have extensive experience across sectors such as petrochemical, refining, nuclear energy, desalination, and HVAC. With deep expertise in meeting complex documentation requirements, we are proficient in non-destructive testing and comprehensive project testing, ensuring the highest quality and reliability in every project we undertake.

Before starting to use our services, please fill in the following form to let us know which type of stainless steel duct system you want to import from China.

WhatsApp us

Choose Caijie

Stretch Your Budget, Not Your Standards !

Before starting to use our services, please fill in the following form to let us know which type of stainless steel duct system you want to import from China.

Once we receive the detailed information regarding your request, your assigned customer representative will contact you shortly.

If you need help, please email us at sales1@caijie-tech.com.