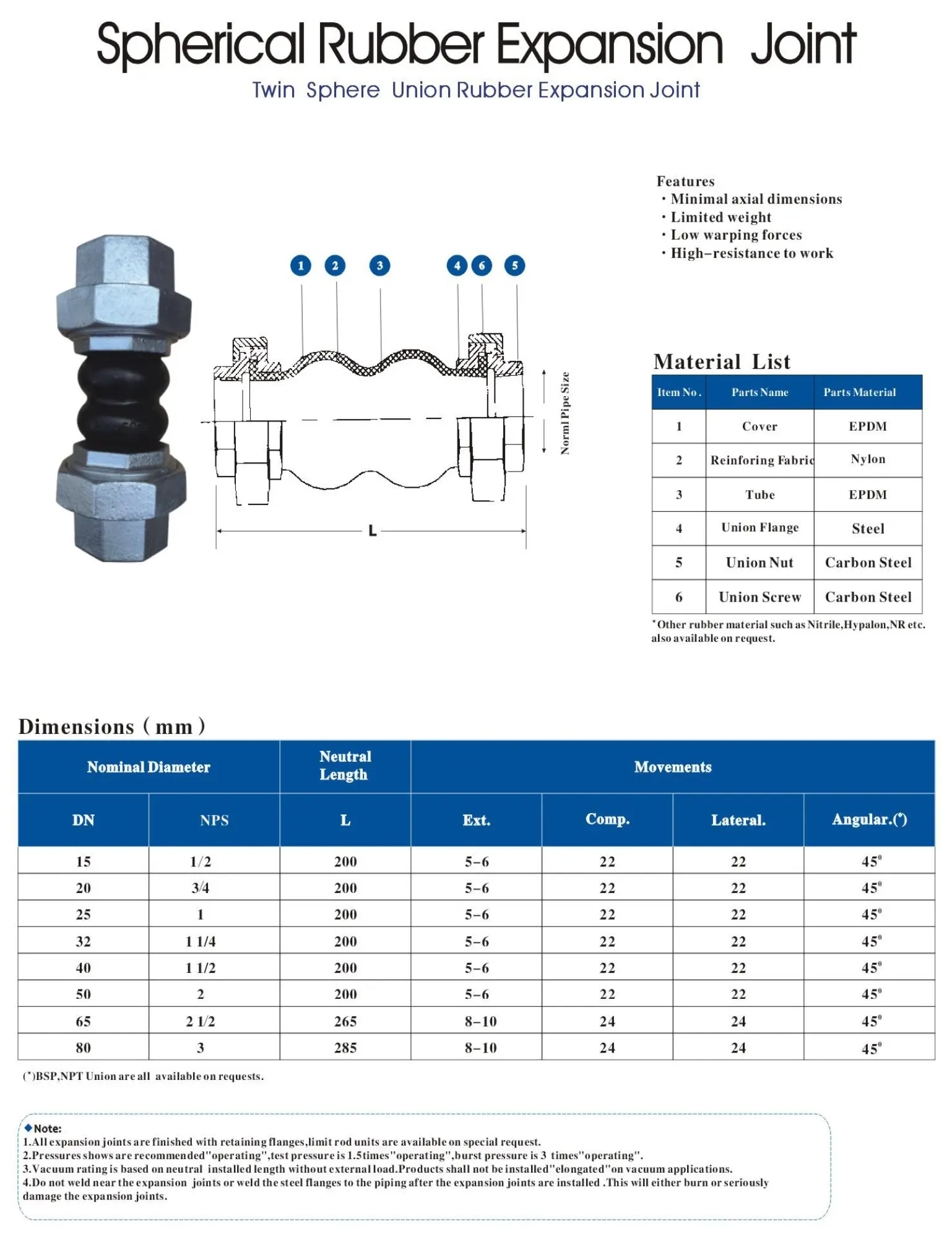

Union Rubber Expansion Joint

Twin Union EPDM Rubber Flexible Expansion Joint malleable Connector

Our union rubber joints are widely used in construction, industrial, and municipal engineering projects. They offer advantages such as vibration reduction, displacement compensation, and corrosion resistance, and are easy to install.

- Corrosion Resistance: Suitable for various media, resistant to acids, alkalis, and oils.

- High Pressure Resistance: Capable of withstanding high pressure

- Good Elasticity: Effectively absorbs vibration and displacement.

- Easy Installation: Threaded connection facilitates installation and maintenance.

Advantage of Union Rubber Expansion Joint

Quality First

By utilizing the elasticity, high airtightness, resistance to media, weather resistance, and radiation resistance of rubber, combined with high-strength polyester cord fabric that exhibits excellent stability under both cold and hot conditions, the material is cross-ply composited and then vulcanized using high-pressure and high-temperature molds.

Exquisite Craftsmanship

- Excellent Vibration Damping

- Strong Displacement Compensation

- High Corrosion Resistance

Quality First

High internal density, capable of withstanding high pressure, with excellent elastic deformation performance. Reduces vibration, lowers noise, offers good flexibility, and is easy to use.

Good performance

- High Pressure Resistance

- Good Elasticity

- Excellent Sealing Performance

Quality First

Used for the lifting and transportation of raw water and sewage, feed water and cooling circulation water in thermal power plants, the metallurgical industry, condensed water, pipeline transportation of chemical substances in the chemical industry, cooling and dilution in the petrochemical industry, and flexible connections for long and short-distance pipelines in other industries.

Wide application

- Adaptability to Multiple Media

- High Temperature Resistance

- Long Service Life

More About Union Rubber Expansion Joint

What is a Union Rubber Expansion Joint?

A union rubber expansion joint is a flexible connector used to absorb movement, vibrations, and thermal expansion in piping systems. It’s often made from high-quality rubber and reinforced with fabric or metal to provide durability.

Usually includes a rubber body, internal reinforcement layers (such as fabric), and metal ends or unions that allow easy installation and removal.

Benefits of Union Rubber Expansion Joints

- Vibration Dampening: Helps to minimize vibrations that can be harmful to both pipes and equipment.

- Thermal Expansion Compensation: Can accommodate the natural expansion and contraction of pipes due to temperature changes.

- Misalignment Correction: Helps in absorbing misalignments between connected pipes, preventing damage to the system.

- Corrosion Resistance: Rubber materials offer resistance to chemicals, water, and environmental factors, ensuring a long lifespan.

Applications of Union Rubber Expansion Joints

- Piping Systems: Used in various industries, such as water treatment, HVAC, petrochemical, and manufacturing plants, where there’s a need to manage pipe stress and movement.

- Pump Systems: Ideal for integrating with pump lines where vibration and misalignment could otherwise cause failure.

- Heat Exchange Systems: They are effective in managing thermal expansion in heat exchangers, cooling towers, and steam lines.

Installation and Maintenance of Union rubber Expansion Joint

- Easy Installation: Discuss the advantages of the union design, which allows for quick installation and removal without disassembling the entire system.

- Maintenance Tips: Explain best practices for maintaining rubber expansion joints to ensure they perform optimally and last longer, such as periodic inspections for wear and tear and checking for leaks.

Get A Quote !