A rubber expansion joint is a vital component used in various industrial systems, designed to absorb movement, reduce vibrations, and prevent damage caused by thermal expansion or contraction in pipes and ducts. These joints are essential for maintaining the integrity of piping systems, ensuring they operate efficiently and safely.

Importance of Rubber Expansion Joints in Industrial Systems

Rubber expansion joints are used to absorb axial, lateral, and angular movement, allowing for flexibility in piping systems. These joints help prevent stress and wear on the pipework, minimizing the risk of leaks or fractures. They also provide noise and vibration isolation, making them crucial in industries such as HVAC, chemical processing, and power generation.

How Rubber Expansion Joints Work

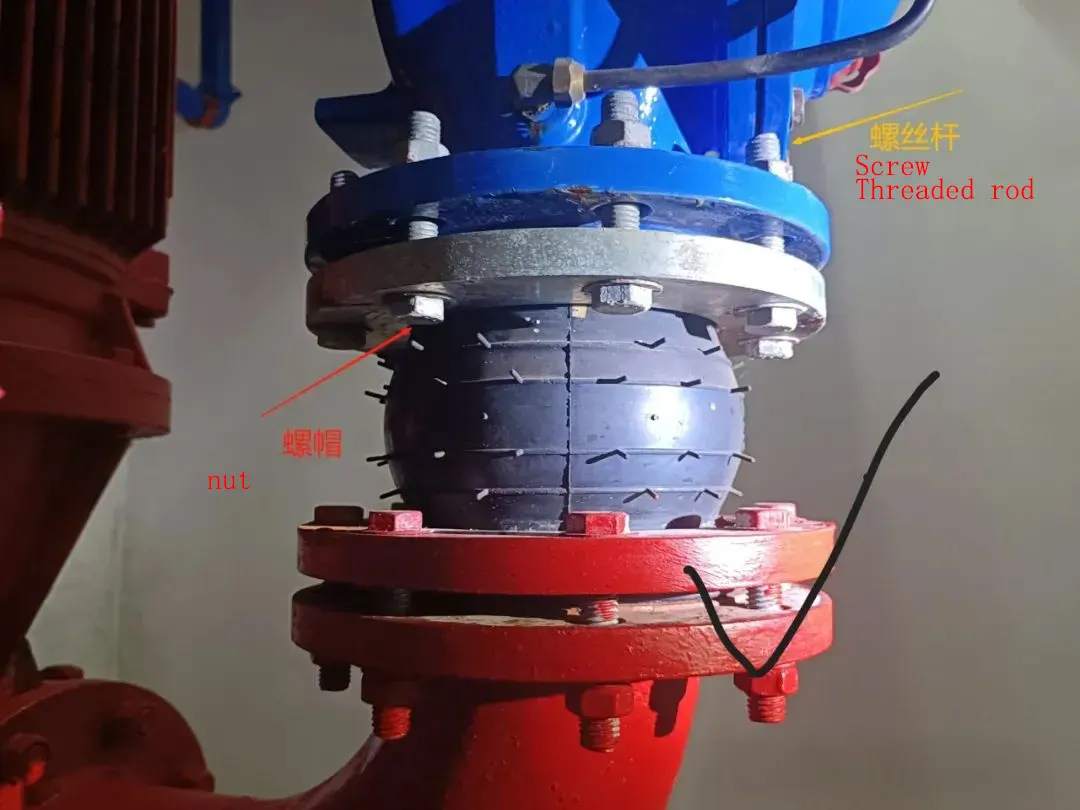

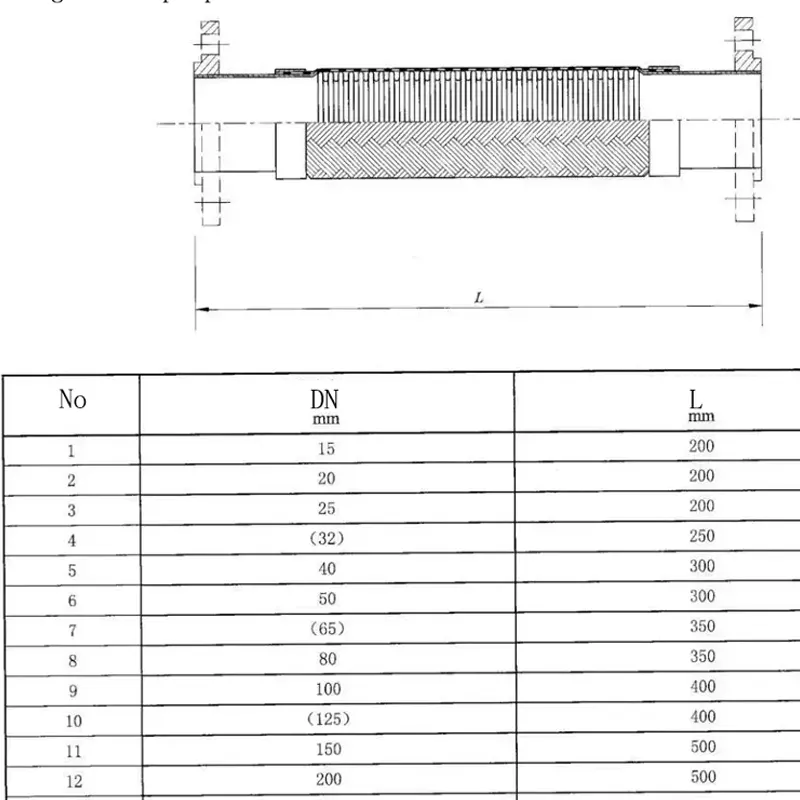

The design of a rubber expansion joint consists of a rubber body and metal flanges, providing a flexible interface between two sections of pipe. The rubber material allows the joint to compress or expand when subjected to temperature changes, pressure fluctuations, or mechanical movement. This flexibility makes it an ideal solution for systems prone to thermal expansion and contraction.

By understanding what a rubber expansion joint is, industries can implement this effective solution to enhance system performance and longevity.