When designing or maintaining industrial piping systems, one of the most critical decisions is choosing the best material for expansion joints. Expansion joints are vital for absorbing movement, vibration, and thermal expansion in piping systems. The material you choose can significantly impact the system’s durability, performance, and longevity. But, what is the best material for expansion joints? The answer depends on several factors, including the operating conditions, temperature, pressure, and the type of fluids or gases transported.

Top Materials Used for Expansion Joints

The best material for expansion joints varies based on specific system needs. The most commonly used materials are:

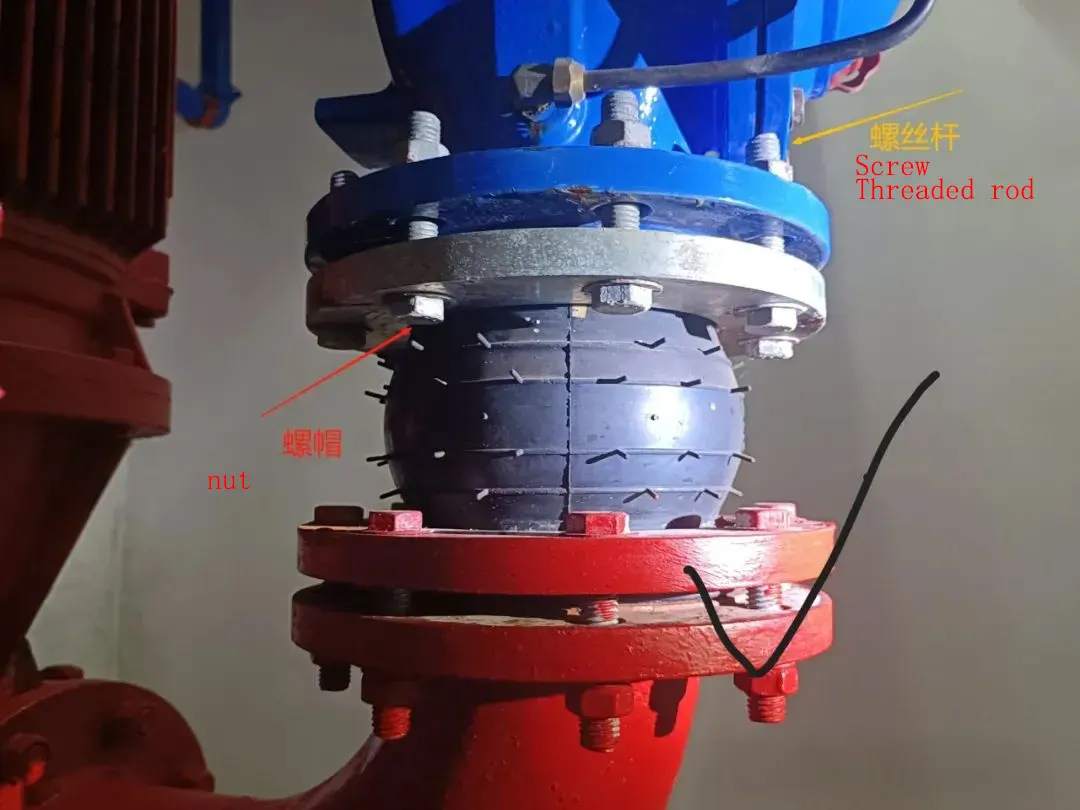

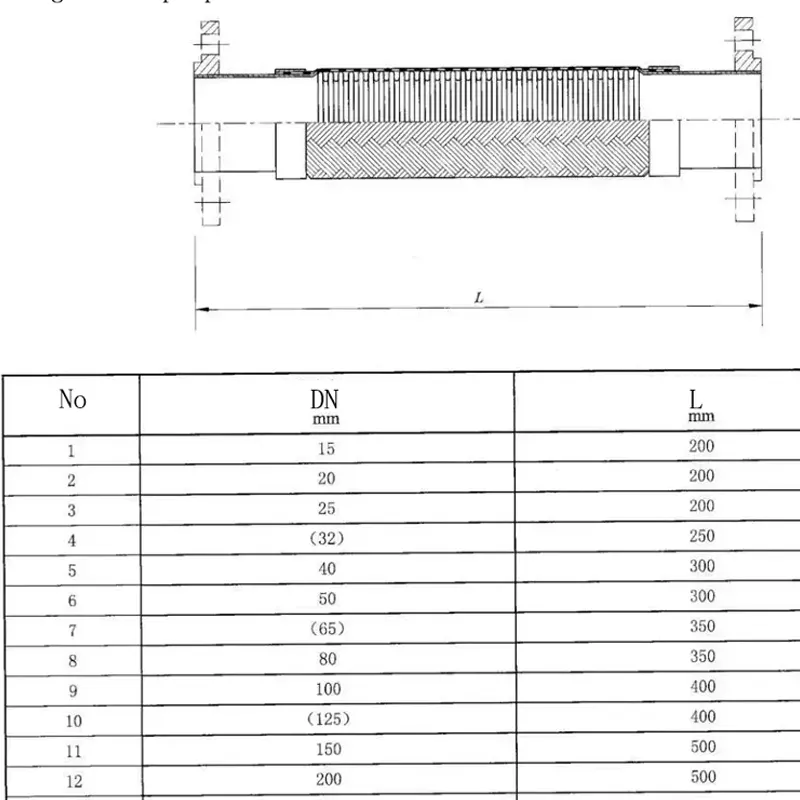

- Rubber: Rubber expansion joints are cost-effective and flexible, ideal for low to medium-pressure systems like HVAC or plumbing. They absorb vibrations and handle moderate temperature fluctuations effectively.

- Metal: For high-temperature, high-pressure, and corrosive environments, metal expansion joints (such as stainless steel or alloyed materials) are the best choice. These joints are highly durable and can withstand harsh conditions, making them suitable for power plants, chemical processing, and oil and gas industries.

- PTFE (Polytetrafluoroethylene): PTFE expansion joints are the best for applications involving aggressive chemicals. They offer superior chemical resistance and can handle both high temperatures and corrosive environments, often used in the chemical processing industry.

- Fabric: Fabric expansion joints are ideal for flexible, lightweight applications. They are often used where space constraints are a concern and are suitable for low-pressure systems.

Factors to Consider When Choosing the Best Material for Expansion Joints

To determine the best material for your expansion joint, consider the following:

- Operating Conditions: High temperatures and pressures may require the durability of metal or PTFE materials.

- Chemical Compatibility: If the system handles aggressive chemicals, PTFE or elastomers are the most appropriate choices.

- Flexibility and Vibration Control: Rubber and fabric joints provide excellent flexibility and vibration absorption, perfect for systems that require movement and noise reduction.

Conclusion: What is the Best Material for Expansion Joints?

In conclusion, the best material for expansion joints depends on the specific requirements of your piping system. Rubber joints are perfect for general, low-pressure systems, while metal joints are best for high-pressure and high-temperature applications. PTFE is the ideal choice for chemical resistance, and fabric joints are best for flexible, space-constrained environments. Understanding the unique needs of your system will help you choose the right material for optimal performance and longevity.